Why You Need a Route Planner [+11 Signs Your Business Needs One]

This article will reveal why you should start using a route planner to plan delivery routes and the eleven signs that your business really needs it.

Home > Blog > How to Plan Better Delivery Routes?

Route TrackingLearn strategies, techniques, and tips that can help you plan better delivery routes so that you plan the best routes for every single delivery.

How long does it take you to plan your delivery routes?

Do your drivers even follow pre-determined directions?

Or do you just give them the address and hope they arrive on time?

How many deadlines and deliveries have you failed to meet because of this?

If the answer is a lot, you need route planning.

That’s why in this guide, we’re going to show you not only how to plan delivery routes with multiple stops, but how to plan the best routes EVERY SINGLE TIME.

So if you want to reduce fuel consumption, minimize returns, missed and failed deliveries, lower planning time, and cut costs while raising profits, then you’ll enjoy this article.

Let’s get started.

Route planning is the act of creating physical paths between multiple locations on the map delivery teams need to take to complete key tasks and fulfill every order in the most efficient way possible.

This means planning delivery routes between:

Pickup points: hubs, depots, warehouses, and facilities where you collect items for delivery

Drop-off locations: multiple destinations where you deliver orders (customer’s addresses)

Typically, the efficiency of a delivery route is determined by:

This requires planning routes beyond the shortest distance between two stops.

That’s why route planners also take into account:

Considering all of this can greatly affect delivery speed, travel time, spend, and the efficiency of each route. Planning a delivery route with multiple stops based on these factors is known as route optimization.

Planning the best delivery routes isn’t just useful. It’s profitable!

That’s because it raises the efficiency of your whole delivery.

Which means more fulfilled orders at a lower cost.

And when transportation costs account for 50.3% of all spending on logistics, it makes sense to try and reduce expenditure.

But taking the time to plan routes (and having drivers ACTUALLY follow them) also raises delivery speed, lowers fuel consumption, and helps you offer new options to customers.

When done correctly, a good delivery route can help you to:

What many companies fail to understand is that delivery produces A LOT OF waste.

It’s up to you to raise the efficiency of your operations to reduce it.

That’s why route planning is so important.

It helps you to keep day-to-day activities on track as you achieve short and long-term goals.

But planning better delivery routes isn’t easy.

Here’s what you can do to improve the process:

Even though the maximum capacity of your delivery doesn’t change, you almost never use it to its full extent.

That means there is room to increase how many deliveries you complete each day.

But this depends a lot on the type of business you operate and industry.

For example, in food delivery, drivers have a pick-up before almost each drop-off. So the number of available drivers varies almost minute-by-minute.

In eCommerce, retail or distribution, drivers typically have one pick-up per multiple drop-offs.

So availability depends on the no. of workers, shifts, no. of vehicles, and payload capacity.

Delivery availability also depends on different times of the week, month, or year.

During peak seasonal demand (Black Friday and Christmas), your delivery may be pushed to its limits. You won’t have enough available drivers or vehicles to fulfill large order volumes.

In that case, you can raise the capacity of your fleet by outsourcing fulfillment to a service provider.

It’s also about having the right staff to fill key roles to meet the demand and workload.

You need to strike a balance between having enough workers during peak times to meet high demand, while making sure payroll doesn’t affect the budget during slow spells.

To plan better routes you’ll need to know the realistic capabilities of your delivery.

This will prevent you from overbooking dates and having overlapping drop-offs.

But that requires knowing how many orders you can physically deliver to customers each day. And since that number never stays the same - that’s impossible.

So what do you do? And how do you calculate the maximum capacity of your delivery fleet?

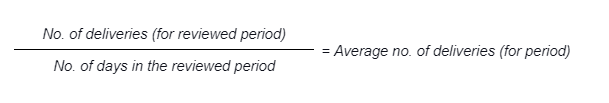

You have to calculate the average no. of deliveries per day.

To do this, take the no. of deliveries you complete per month and divide it by the no. of days.

This gives you a rough estimate of how many deliveries drivers can physically handle.

You should do this for each driver individually, but also for the fleet as a whole.

It’s also worth doing it regularly.

A good idea is to calculate the average number of deliveries for the previous month. That gives you a better sense of how many orders you can fulfill in the current month.

A more granular approach to evaluating the maximum capacity of your delivery is to calculate the average time it takes to complete each activity in the delivery life cycle.

That means determining how long it takes to plan routes, dispatch drivers, pick-up orders, reach the drop-off destination, and service customers.

This gives you a more accurate picture of your capacity and helps you to set a limit on how many stops you can add to each route.

Having depots and fulfillment hubs closer to customers means more efficient routes.

That’s because it affects the distance to and from pick-up locations.

If you position depots outside the delivery area, drivers have to travel longer to pick-up orders.

That means more time on the road, greater fuel consumption, earlier starts, and, in general, inefficient delivery routes.

But setting up a depot close to the drop-off zone isn’t always an option.

These days warehouse space in cities is scarce and rent is unaffordable for most SMBs. That makes it extra difficult to effectively do delivery routing in urban areas.

In fact, it’s the main reason why Amazon is investing most of its $35,046 million on raising storage capacity.

One workaround is to have multiple small sites and use centralized multi-depot planning when routing vehicles for pickup.

Another is to use brick-and-mortar stores as fulfillment hubs, and pick up orders directly from the shelf.

Whatever the case, both solutions allow you to keep your inventory and pick & pack centers close to customers.

Not every order is the same. Nor is every customer. So neither is every delivery.

Some have greater value. Others have to arrive sooner.

So when planning a delivery route, you’ll need to take this into account, and set the priority for each order and delivery.

Common reasons for different order priorities include:

Doing this helps you to maintain order accuracy by understanding which orders have to be delivered first:

The higher the priority the sooner you need to complete that drop-off.

That makes it easier to sequence the stops for each route.

If you have multiple high-priority deliveries far from one another, then you’ll know how to divide them among different drivers.

And you’ll know this if you keep a day-to-day list of priority orders.

The time drivers and couriers spend with customers affects the efficiency of a route, as well.

This is the service time your employees use to interact with the customer, drop off orders, and collect proof of delivery.

Depending on what you deliver, the relationships you have with customers, or their requests

this can also include:

All of this takes time to do. If you don’t account for it when planning routes, drivers run the risk of not making other deliveries on time. And that’s a problem:

According to delivery statistics, 96% of people cite customer experience as an important part of their loyalty to a brand.

Another 13% of customers will never do a repeat order if their delivery doesn’t arrive on time.

To account for service time at the customer’s doorstep, evaluate the average time it takes to service a customer.

Adding service time when planning routes gives you a more accurate number of stops each driver can successfully pull off per route.

It also puts less pressure on drivers to handle as many tasks as they’re physically capable of doing.

It also means they won’t rush their interaction with customers. That means they can provide exceptional service and build trust with customers through delivery.

Delivery routes with multiple stops depend on internal factors as much as they do on external ones.

The type of roads delivery agents drive on, the distance between drop-offs and the amount of traffic congestion they encounter all affect delivery time.

A more direct route may not always be the best path to take if the road conditions cause drivers to miss the delivery deadline.

So it’s worth evaluating external conditions that affect the speed of delivery when planning a delivery route.

This can include:

Communication is key for streamlining route planning activities.

When it comes to internal communication, focus on improving fleet dispatching:

All of this helps dispatchers adjust routes in real time.

This kind of dynamic route planning can help you plan better routes as you leverage input from drivers who are already on the road. And that can make the delivery more efficient.

It also helps if drivers can speak directly with customers.

Drivers can let customers know their estimated time of arrival (ETA). This can minimize the chance of absent customers, missed, or unsuccessful deliveries.

It also minimizes how much drivers interact with dispatch. Which means more focus on the road and greater driver safety.

All of this can be easily applied with modern tech solutions. (But more on that later)

Collecting, analyzing, and evaluating delivery data is KEY for improving the performance of your delivery.

It can help you to:

It also means you can make more accurate assessments of your delivery based on data and key metrics in delivery logistics.

This means that you can continuously improve how you plan routes, and all other activities.

And overcome the challenges in last-mile delivery, disruptors such as COVID-19 or the evolving consumer behavior.

Let’s face it:

Manually planning routes isn’t efficient anymore.

It takes a lot of time, effort, money, and you typically have to rely on individuals with a specific skill set.

More often than not you also have to plan fixed routes, as well. That leaves you no room to build an agile delivery.

So what do you do?

You embark on the digital transformation of your business to build a strong delivery through automation.

As a matter of fact, 51% of companies are already investing in automation, with eCommerce (66%), food and beverage (59%), and third-party logistics (55%) companies leading the charge.

How do you automate route planning?

You incorporate route planning and optimization software.

This type of software operates using cloud technology. Which means you can access it from any office, dispatch center, or transportation hub.

It also enables you to plan and optimize routes based on parameters that YOU want to incorporate.

The software gives you more visibility, flexibility, and control over last-mile delivery by allowing you to:

This means that you can do all of the above-mentioned steps on one centralized system.

And in doing so, plan better delivery routes.

A good delivery planner is all about organizing your team to do the right tasks at the right place and at the right time.

Doing so will make your business more efficient, and your delivery more productive.

So keep in mind:

Now, it’s time to hear what you have to say.

How can better delivery routes improve your delivery?

What about using the software for automating your operations?

Optimizing delivery routes is crucial. But if you’re not sure what kind of tools you need, don’t worry. That’s why we’re here.

We have everything you need to start improving your delivery.

This article will reveal why you should start using a route planner to plan delivery routes and the eleven signs that your business really needs it.

See how to plan a route with multiple stops on Google Maps (step by step) and why avoid it when planning delivery routes + Use Cases and more.

See what route data you need to collect, track, and evaluate to plan and optimize routes for your delivery. And how to do it easier with routing...

Be the first to know when new articles are released. eLogii has a market-leading blog and resources centre designed specifically to help business across countless distribution and field-services sub sectors worldwide to succeed with actionable content and tips.