This is a complete guide to the perfect order metric.

In this in-depth guide, we’ll explain:

- What is the perfect order metric

- How to calculate the perfect order metric for your delivery

- How to use this KPI to achieve perfect order fulfillment

- Lots more

So if you’re ready to start measuring the perfect order rate to deliver more goods accurately, on-time, and damage-free, this guide is for you.

Let’s dive right in.

What is the perfect order metric?

Perfect Order Metric (or Perfect Order Rate) is a collection of key performance indicators (KPI) in delivery logistics. Perfect order measures show you the percentage of how many orders are fulfilled successfully and without any incidents including inaccurate orders, late deliveries, or damaged items.

Order metrics you need to track

The goal of measuring the perfect order KPIs is to show the effectiveness of your operations to fulfill orders according to customer requirements over time.

This metric also represents how well your organization delivers goods to customers. But also the number of successful orders that are completed without a hitch.

So tracking the perfect order rate over time indicates delivery success rate, as well as your ability to keep promises to customers.

That’s why it’s one of the ways you can determine consumer satisfaction with your delivery.

To get an accurate account of your perfect order rate, you’ll need to track these four metrics:

#1 Orders that arrive on time

On-time delivery (or orders that arrive on time) consists of deliveries completed within the specified time window.

Either you or the customer determine the date (and time) of delivery. But once the delivery is scheduled, it’s up to you to fulfill the order within that time frame and without any delays.

On-time delivery is critical for customer satisfaction.

The longer customers wait for deliveries, the more likely they are to stop ordering goods from you.

In fact, 69% of consumers say they will stop buying from a brand if their orders don’t arrive on time.

#2 Orders that arrive with no damage

Orders that arrive without damage (damage-free deliveries) are those that arrive intact to the customer:

Orders that include products that were in no way, shape, or form dent, defective, or broken during any stage of delivery.

Damaged products or damaged items during delivery are a big problem in parcel shipping.

In fact, there was a 19.1% increase in damaged packages in 2020 due to the impact of COVID-19.

What’s interesting is that most damaged goods arrived to customers via established carriers.

At least one in ten ecommerce packages arrived damaged in 2020, with UPS accounting for 11% of damaged deliveries, followed by USPS (10%) and FedEx (11%).

If a damage does occur, it’s important that you find out why the package was damaged and record the reason.

That’s the only way to ensure damages don’t happen in the future.

#3 Orders with correct invoicing and documentation

Order accuracy depends a lot on your ability to generate the correct invoice and documents for each order.

Invoicing mistakes may lead you to:

- Charge more money to a customer, which may prevent you from retaining them.

- Charge less money to a customer, which causes you to lose money.

- Send the invoice to the wrong customer, which causes you to lose two customers.

In all three situations, you risk damage to your reputation, churn, and customer retention.

On the other hand, improper order processing or filing can cause even more problems.

Order documentation mistakes can lead to:

- Packaging the wrong items

- Delivering to the wrong customer

- Delivering to the wrong address

- Missing delivery dates and times

All of these situations cause you to lose money. And they can have a negative impact on customer service.

That’s why most delivery companies are moving away from paper-based systems and manual delivery planning.

#4 Orders with correct labels

Orders with correct labels help you process orders and prepare them for delivery.

Similarly to incorrect documentation, incorrect labels cause dissatisfaction among customers.

There is nothing more frustrating to a customer than receiving the wrong order.

Or the wrong products in that order.

Or not receiving it at all due to you mislabeling their order.

Automating the pick and pack process can help you avoid such issues.

How to calculate the perfect order KPI

Here’s how you can measure the perfect order rate:

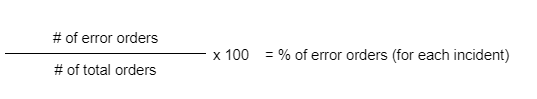

First you need to determine the percentage of error orders for each incident:

To do this, divide the no. of error orders (per incident) with the total no. of orders for a period and multiply it with 100:

(Subtracting % of error orders for each incident gives you % of orders delivered on time, without damage, and with accurate documentation)

This can help you to determine what is the biggest issue for your delivery.

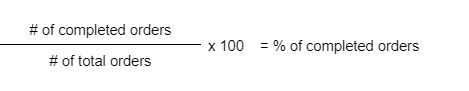

Next, you need to calculate the percentage of total completed orders.

You can do this one of two ways:

Either divide the no. of completed orders with the total no. of orders:

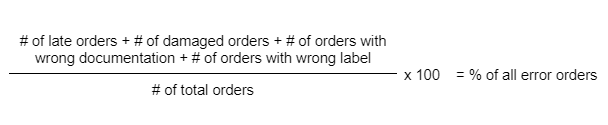

If, for some reason, you don’t know the amount of completed orders, you can add error orders for each incident, divide it with the total no. of orders:

(Subtracting % of all error orders gives you % of completed orders)

Once you’re done you should have:

- % of completed orders

- % of orders delivered on time

- % of orders delivered damage free

- % of orders with accurate documentation

Multiplying all of them gives you the perfect order index or perfect order metric:

What is a good perfect order rate?

A good perfect order rate should be above 95% (at least).

But, in reality, this number is much lower for most delivery services.

In fact, the average perfect order index in the United States is 90% (American Productivity and Quality Center).

Still, if you want to be a top performer and achieve success, your goal should be 95%.

Here’s why:

Why do your order metrics need to be perfect?

Brand loyalty and customer satisfaction increase when you fulfill customer expectations.

In fact, 96% of all customers say customer experience is an important part of their loyalty to a brand.

When a customer fails to receive the right items on time, they are far less likely to purchase again in the future.

Actually, 13% of shoppers never return for another purchase if the delivery doesn’t arrive on time.

Sadly, here you don’t only deal with the loss of revenue.

Your business also has to deal with rising expenses in terms of covering the cost of:

All of this takes a toll on your bottom line.

In fact, retailers lose over 25% of the purchase price on returns alone.

That’s why, by maintaining a good perfect order rate, your delivery:

- Reduces errors and raises order accuracy

- Saves time and money on fixing mistakes

- Makes it convenient for customers to order

- Meets customer expectations and values

- Increases customer retention and brand loyalty

- Makes you more competitive on the market

- Helps to create relationships with customers

So…

Is the ideal perfect order rate a realistic operational goal?

Yes. And you should strive to achieve that goal.

Not to say that it isn’t difficult. But it will help your delivery service grow and scale.

To achieve the ideal perfect order rate, here are some steps you need to take:

Step #1: Evaluate the current situation and measure the perfect order rate.

Step #2: Keep track of errors that lead to incidents that lower the perfect order rate.

Step #2: Identify where in the supply chain these mistakes happen.

Step #4: Employ strategies to improve each stage of delivery and minimize mistakes.

Step #5: Use technology to analyze and optimize delivery performance.

eLogii helps you optimize fulfillment for perfect order metrics

eLogii can help you to improve your perfect order measure.

How?

Our SaaS software solution:

- Tracks and helps you to easily evaluate the perfect order rate

- Automates how you manage your deliveries and order data

- Continuously optimizes your delivery operations for better performance

Here’s how you can achieve this three things with eLogii:

Monitor perfect order metrics on the dashboard

The eLogii dashboard can automate every stage of the delivery process, including how you monitor the perfect order metrics.

As a cloud-based solution, it collects a lot of data.

This includes tracking fleet and driver activities and collecting reports from the field.

That enables you to see in real time the success rate of each delivery; whether the delivery was completed, arrived on time, missed, or failed.

But also an at-a-glance view of your entire delivery operation.

Maintain high order accuracy rates

The eLogii dashboard can connect to your OMS in three ways:

- via data upload (.csv files): upload data in bulk directly to the dashboard

- via API integration: connect and automatically transfers orders from your OMS

- manually: uploading orders one at a time for greater control

Uploading orders to the dashboard transfers them to tasks with all the necessary information to successfully complete each delivery.

So if you’re unsure about the order label, documentation, or any other information you can check it to ensure greater order accuracy.

The information is then transferred automatically to the driver app. There drivers can view all the data as you have uploaded or entered into the system.

Track historical data and KPIs

The eLogii software solution takes a platform approach to delivery management.

This means that it operates using cloud technology.

Cloud storage means you can collect and store more data. That gives you greater access to more data than before.

This feature allows you to track historical data for every previous delivery. So it’s easier to identify problems that cause your perfect order metric to drop.

For example, reasons behind delivery delays, failed tasks, or missed deliveries.

At the same time, the eLogii dashboard has an analytics module.

This helps you to automatically observe and track key metrics in delivery logistics that ensure you reach the perfect order metric for fulfillment.

Basically, with these two options, you can:

- Easily use previous information, which saves you the trouble of creating new tasks, orders, routes, or other activities.

- Get access to previous order and delivery information, crucial data about customers and their orders.

- Evaluate all historical data to see what works and what doesn’t work, so you can continuously optimize your delivery.

eLogii is an end-to-end software solution for managing delivery, distribution, logistics, and field service operations.

Our goal is to make it easier and more efficient to manage your activities, regardless of the industry you work in.

This requires optimization through automation.

In fact, more than half (or 51%) of businesses are investing in automation of delivery processes this year alone.

And digitally tracking and monitoring KPIs like your perfect order index is the only way to achieve continuous performance improvement.

That’s why we can help you beyond this: