Many business owners find inventory and warehousing to be sources of stress. They do not see these aspects as business opportunities.

Excessive caution consumes working capital in addition to raising holding costs.

If you run out of stock, you might lose loyal customers, and they might find another online retailer.

Optimizing inventory is about making customers happy. It also involves preserving as much capital as possible. Striking this balance ensures a more efficient and profitable business operation.

Thus, this article breaks down inventory optimization and why it matters. With the right strategies, it will help you kick-start the process in your company.

What Is Inventory Optimization?

Determining the right amount of stock is part of optimizing your business inventory. It ensures you have the optimal inventory level and helps streamline your operations.

The aim is to prevent running out of stock and keep customers waiting. At the same time, you aim to invest the least amount of working capital in inventory.

Though these two ideas might clash, like oil and water, they don't. You won't decrease your stock without careful consideration.

Rather, adopt a gradual approach to optimize your supply chain. This allows you to decrease inventory without worrying about running out of stock.

But what's the significance, and why is it vital for advancing the growth of your business?

Why Is Inventory Optimization Important?

Streamlining inventory is vital for creating a strong business with a healthy cash flow.

#1 Stock Shortages Can Lead You to Losing Loyal Customers

If you cut inventory too fast, you'll likely run out of certain SKUs.

Informing a paying customer that a product is out of stock is detrimental to business. It often leads to losing a sale and may jeopardize future business from loyal customers.

#2 Inventory Constrains Cash Flow

The more money stuck in inventory that doesn't sell for months, the less cash you have.

This could mean delays in starting an R&D project or launching a new marketing campaign.

You could indeed get a loan for other projects. But keep in mind that business loans have interest rates of around 8–10%.

Indeed, you might consider taking out a loan for other projects. But bear in mind that business loans typically come with high interest rates, around 8–10%. Additionally, they need extra time and effort to navigate.

Stocking too much is an error that can hinder your company's growth potential in a major way.

#3 More Inventory Results in Higher Holding Expenses

The estimated holding or carrying costs fall within the range of 15–25%. This can vary based on the product and industry.

Maintaining inventory for one month versus three months makes a significant difference.

Keeping that much inventory will result in extra ongoing costs. Namely, you could pay 50% of the original product cost.

So, you should discover inventory levels that prevent stockouts. At the same time, you want to use much less cash and warehouse space.

Let's take a closer look at the process of achieving your optimal inventory level.

How Can You Optimize Inventory?

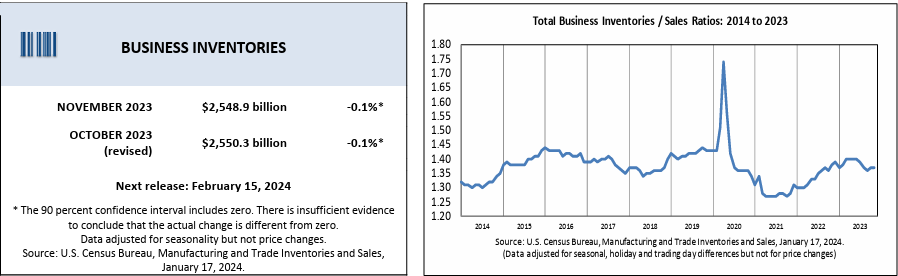

In November 2023, the total business inventories/sales ratio was given as 1.37. This means that for every dollar of sales, companies held $1.37 in inventories.

(Image Source)

That is equal to a little over one month of sales.

If you have a much larger inventory than that, it's a good idea to start safely reducing your stock.

Determine the optimal reorder levels for your products

To reduce your inventory, start by figuring out the best time to reorder each product in your stock.

Fortunately, it's simpler than it sounds. To determine it, just multiply your average daily sales by the lead time for the product.

Following that, incorporate a safety buffer. This buffer ensures you won't run out of stock during peak sales. It also helps keep enough inventory if lead times become longer than expected.

Following a dedicated guide on the inventory reorder point will help you find the right formula to calculate it.

Determine a safety buffer to prevent stock shortages

For practical reorder points, factor in a safety stock level for each product.

Safety stock involves calculating the standard deviation for both sales and lead times. By anticipating worst-case scenarios, you can prepare for them.

Anticipating a stockout doesn't require a Mayan calendar; just analyze the data.

Boost inventory turnover

For individual products, rely on reorder points. On a broader scale, measure and boost overall inventory turnover.

Track turnover rates for enhanced long-term inventory planning and benchmark against industry leaders.

The rates help you know how much stock to keep and when to restock.

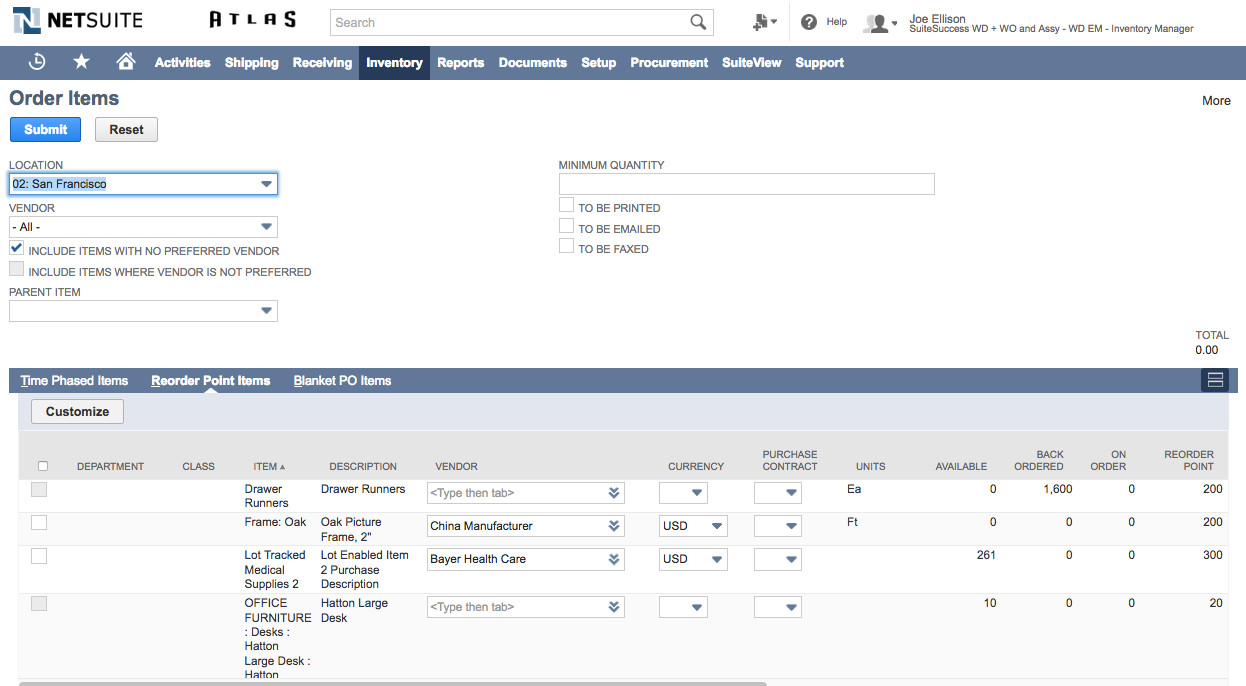

Use an ERP for efficient inventory management and faster replenishment.

An enterprise resource planning (ERP) solution aids in the management and tracking of your inventory.

It tracks product units across the supply chain and alerts you when it's time to reorder.

This simplifies maintaining optimal inventory levels consistently.

You can register many suppliers with payment methods and easily reorder when needed.

(Source)

An ERP makes it easier for everyone to follow a detailed inventory policy.

Even with an ERP, businesses often deal with phantom inventory or inaccurate records.

In the end, the responsibility for inputting and validating data lies with humans.

Enhance the precision of your inventory data

The data within an ERP is valuable only when it reflects accurate inventory information. Otherwise, metrics like fill rate and other KPIs may be significantly inaccurate.

Regularly count your inventory and compare the actual numbers with your records to fix this problem.

Putting in extra effort is the tradeoff. It allows for much better-managed supply chain data control.

Even with inventories that are 100% accurate, there are issues that an ERP cannot resolve.

For the physical shipping or movement of goods, a specialized solution is necessary.

To meet customer needs and save on inventory costs, you should speed up your logistics.

Increase Logistics Speed of Smaller Inventories

When managing inventory, the first step is to reduce stock. Then, improve warehousing processes.

Reducing inventory and refining warehousing processes is crucial, but it's not enough. You also must optimize logistics and shorten lead times in your supply chain.

Managing a supply chain with many stages might seem daunting. You need to map and enhance lead times between each factory, warehouse, and distribution center.

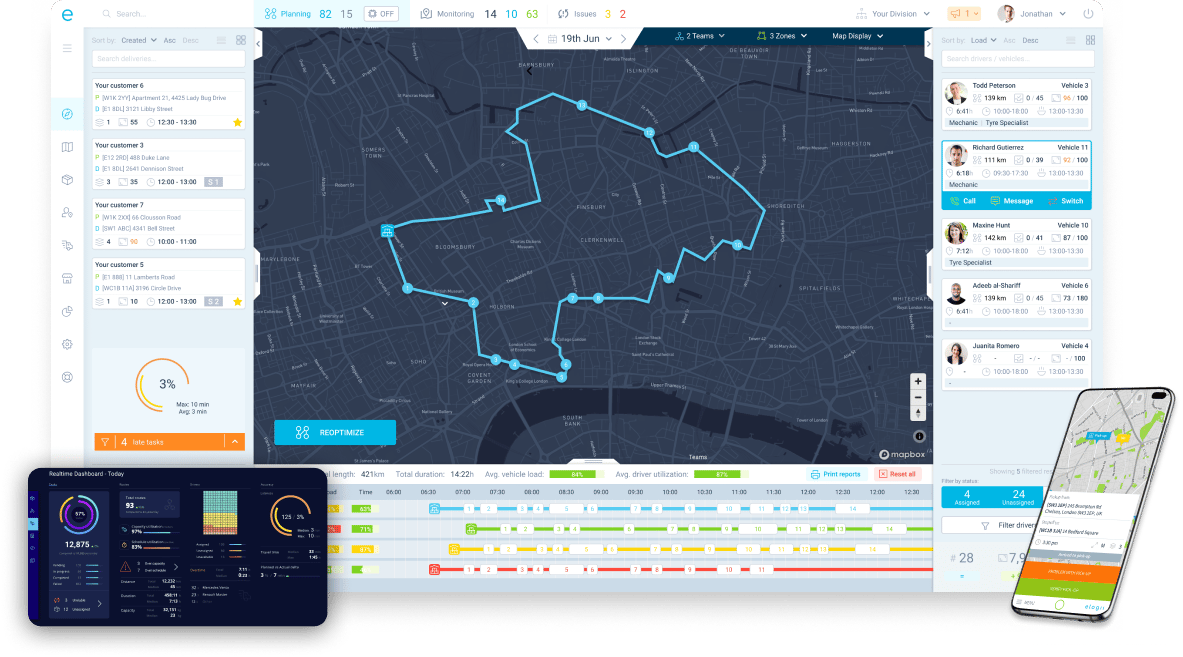

Achieving efficient planning and routing manually is impossible. Yet, with route optimization software like eLogii, you can identify the ideal route in only a few minutes.

Effortlessly coordinate large-scale resupply shipments with eLogii

eLogii simplifies planning resupply shipments for all your distribution centers and warehouses.

Our software can handle multi-day routes, even up to five weeks ahead. You can plan them in minutes.

It considers practical factors such as driver schedules, delivery time windows, vehicle capacities, and features. These include loading ramps and refrigeration.

Rather than spending hours or days on a spreadsheet, your shipments will be en route in no time.

Save time with streamlined route planning and shipment distribution

Efficient manual distribution of orders is nearly impossible. Many companies use a basic zip code or service area system. This, in turn, seldom results in optimal delivery times.

Our software can assist in cutting mileage by 20% or more throughout your entire fleet.

Enhance efficiency with insights derived from data

Use our analytics dashboards to track crucial KPIs. Detect and address issues within your logistics chain.

We offer access to real-time data through the eLogii Mobile App. It utilizes GPS tracking and delivery prompts to track the progress of each driver.

Identifying issues, such as underutilized drivers or vehicles, busy weekdays, and underserved areas, becomes effortless using eLogii.

Leverage the historical delivery data for demand forecasting and inventory planning with ease. Seasonality becomes manageable when guided by data in your planning.

Conclusion

Overstocking is an unfavorable business choice, often driven by unavoidable circumstances.

A sluggish or undependable supply chain requires a larger stock.

With eLogii, you can address this challenge by accelerating your lead times and internal distribution processes.

This approach allows you to decrease your inventory. The result is a significantly lower risk of stockouts.