How to Win Over Customers with Delivery Management Software?

In this article, we reveal how delivery management software can help you to win more customers, handle more orders, and make more money.

Home > Blog > 15 Biggest Mistakes in Delivery Management (for 2025)

Delivery LogisticsThese are the 15 biggest mistakes you can make when managing your delivery. We dive deep into why you might make them and how to easily fix them.

Mistakes happen. Orders get mixed up. Deliveries get lost. Items get damaged en route. And hidden costs appear out of the blue.

How you handle challenges like these is what defines the success of your delivery operations. Not just how many orders arrive at your door.

In this post, we take a look at some of the most common mistakes that happen in delivery planning.

You’ll see the root of each problem, and how to effectively weed it out.

We’ll also let you in one solution that helps you handle all of them.

(But more on that later)

Right now, if you want to ensure that each product makes it to your customers’ hands with every drop-off, this post can get you there.

Consumers value choice. If a person has no choice, he or she won’t have a sense of participating in the decision-making process. Too many choices and the individual is less likely to decide at all.

That’s the psychology of choice.

According to expert Sheena Iyengar, consumers are six times more likely to buy a product or service if they face 5-7 different options.

The bottom line is that choice makes people happy. So, whether you run a food delivery in your restaurant or running an uninterrupted pharmacy delivery, it’s up to you to include four-five options along with your standard delivery.

There are several factors to consider. You can use speed, time of arrival, cost, location, and other factors to build your offer. The most common types of delivery include:

Building up your offer around customers’ needs and preferences makes it more valuable. It’s also more convenient and flexible.

And if customers see it as such, they will want to use it more, and buy more products at the same time.

Your customers don’t have the patience to wait for weeks to receive their orders anymore. In fact, 44%, or almost one in two people want their order delivered within two days from the purchase.

But thanks to Amazon, and the companies’ move to free same-day shipping for their Prime members, even that has changed. The reality is that the entire market is focused on rapid fulfilment.

The good news is that customers are willing to pay for speed. According to a survey, 88% of consumers are prepared to pay for faster, same-day delivery.

So, there is room for your organization to offer fast delivery to customers. All you have to do is take advantage of this opportunity.

The solution is to focus on rapid local delivery fulfilment.

Offering same-day delivery to customers closest to your supply chain means reducing delivery windows, but increasing delivery cycles. Simply put, a driver will complete multiple deliveries over multiple delivery runs.

To make this work, you will have to rethink your delivery strategy to remove non-essential steps via optimization.

Luckily, the investment will pay off since most of your customers are prepared to reward your decision to offer same-day delivery.

People love free shipping. In fact, it’s the top reason why 79.8% of shoppers in the US choose Amazon over any other company.

So, if you are looking to know how to compete with Amazon delivery, and other giants like Walmart, Dominoes, Alibaba, AliExpress, you have to expand your offer to include free delivery.

However, many organizations are reluctant. Whenever someone puts the word FREE near a product or service offered, most companies assume they will lose money. But that’s not the case here.

If you increase the time it takes to fulfil an order and establish more expensive delivery options, you can offer free delivery without losing any money.

For example, you can set up a 7-day free delivery. The price of priority options (next-day or same-day delivery) could cover the operating costs. And because you drop them off once a week, order volume will maximize route density and minimize the cost per delivery.

Another way is to set the price based on different delivery zones. For example, you can offer free delivery at the local area (3-5 kilometers), while the rate for nationwide or international delivery would cover those costs.

How do you deliver products or services to customers? Do you operate a private fleet? Or do you use a third-party provider instead?

Selecting a delivery rate for your organization is vital if you want to have a positive bottom line and keep your customers happy. And that requires balance.

If the rate is too low, you risk making your delivery financially unsustainable. The price of delivery won’t be able to cover the cost of operations.

On the other hand, if the rate is too high, you risk disappointing customers. The price of your service (plus product) could scare them off, and lead them to your competitors.

If you use a third-party provider, then you should calculate the delivery rate manually. And there are a few different factors you should consider:

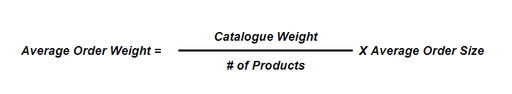

Here’s an example of how to calculate the price of delivery according to the average order weight:

You should also see how (and how much) your provider charges for their service. Most 3PL companies do it per:

Once you have the cost of delivery, you can add it as a surcharge, or directly include it into the total price tag (the price of product + price of delivery).

If you handle the delivery yourself, you can afford to lose money on different delivery options, like free delivery.

At the same time, you cover all operational expenses. So, you need to take into account payroll, fuel, vehicle and equipment maintenance, and other expenses when determining the price of delivery.

That’s why it’s also vital to reduce operational costs as much as possible.

Trimming the budget is an important part of the business. And when it comes to your delivery, it’s critical.

Unlike production or sales, delivery isn’t a core business activity. So, you always have to maintain strict control over operational expenses.

If you don’t, costs can easily spiral out of control, eat into your profit margins, and be a burden for your customers. And your customers don’t appreciate paying for delivery.

In fact, when it comes to eCommerce statistics, it’s the biggest cause of cart abandonment among consumers.

If you want to prevent that from happening, you must look for cost-cutting opportunities:

Good communication is the key to excellent customer service. It’s what builds trust and nurtures relationships between your brand and your customers.

Strictly speaking, it creates fans out of your customers. And according to Kevin Kelly, all you need is 1000 true fans to be successful.

But what most companies forget is that people talk to people. Organizations spend millions on ad campaigns and social media, without ever letting their employees speak to customers directly.

That’s a huge problem, especially in delivery.

Not letting employees speak to customers (or customers to employees) creates a break in communication. It prevents your brand from listening to your customers.

Without hearing them, you will remain deaf to your customers’ pains, needs, preferences, and desires. And this can create a gap between what you offer and what customers actually want.

And the problem is even worse when it comes to face-to-face interactions.

In delivery, a customer will get a first impression only after a delivery driver arrives at his door. And since the driver represents your company, how he presents himself is the measure of your brand.

Letting your staff talk to customers, especially your teams in the field, can give your organization a boost in customer experience.

First, it lets customer service listen to feedback and provide suggestions on how to improve your delivery. For example, if there is a repeating problem, customer service can point it out, and then team leaders can find a solution that works for the entire operation.

Drivers can provide a much better service, as well. Sending a simple message to a customer before reaching the drop-off boosts the driver’s chances of leaving a good first impression:

Hi John,

Your delivery is 15 minutes away.

See you soon!

Mark from delivery

A simple gesture like that gives your brand a personal touch to customer interaction. It makes a company, something distant and artificial, feel closer and more trustworthy, like a person.

Consumers love to be involved when shopping. That’s why fashion outlets have changing rooms, or why grocery stores allow people to smell, feel, and even taste fresh food.

The same reasoning applies to online shopping. Because the online experience is limited to sight (and sometimes sound), the more information people can see (or hear) about the product or service, the more they will feel involved.

And when it comes to delivery, the principles are the same.

Customers want to be involved with their delivery as much as possible. They want to choose the date and time when their delivery will arrive, where it’s delivered, and even who delivers it.

They also want to be able to see where their delivery is at any moment in time. So, it’s up to you to make sure that they can.

Using delivery management software with geolocation and GPS positioning and tracking lets you monitor the location of each delivery operative in the field using a virtual map.

After a dispatcher assigns a task to a driver, customer service can use the software to generate a tracking link and send it to the customer.

The customer can use the link to track his or her delivery in real-time. These links usually also show expected times of arrival, so customers know when the delivery will arrive and can plan their day accordingly.

Unexpected things can happen to products before they are picked up from inventory. A lot more can happen further still en route to their destination.

In any of these situations, products can get damaged. It’s up to you to reduce that risk.

The safe packaging of your products ensures your products remain secure during transport. More importantly, though, it’s a guarantee that all items arrive intact to their destinations.

From bags, boxes, and bubble wrap to pallets and wooden freights, there is a lot to consider when choosing the correct packaging. That also relies on the size, shape, and material of the items.

But the most important thing to remember is that the packaging you choose is durable, as well as branded and nice to look at.

Apart from that, you need to have adequate equipment to secure each package inside the vehicle. Shelves, containers, straps, and lashings all prevent the packaged items from moving as your vehicle goes through traffic.

Beyond packaging, think about specialized vehicles. Some industries have specific standards or guidelines you will have to follow. For example, transporting medicine, or using refrigerated vehicles in food or beverage delivery.

Because there is limited storage space in each vehicle, the amount of products you can deliver per route is limited, as well. That means the capacity of your fleet is also finite.

Unless order volumes match vehicle capacity, there is a good chance that drivers will have to resupply before completing all of their stops. This can help you plan multiple depot locations across the last mile.

Moreover, vehicle capacity shows how much space you are wasting per delivery. If the space in a vehicle is not managed correctly, you are wasting valuable resources. So, you need to ensure that:

Despite your best efforts, mistakes can happen. A delivery may get damaged during transport. Or it may be misplaced at any point in the delivery lifecycle.

If this happens, you need to have a system in place that can deal with these situations fast and without too much hassle for the customer.

Reverse logistics help you handle the return of deliveries, regardless of the cause.

For example, if a customer isn’t satisfied with an item (his order got mixed up or the item was damaged en route), reverse logistics helps drivers to pick up a replacement and deliver it as soon as possible.

In case the item was lost or misplaced, drivers can easily contact dispatch and send the product with another driver.

A fast reaction to unplanned situations like these is the hallmark of a good delivery. It’s what allows you to maintain a high quality of service, which keeps customers happy.

What area does your delivery cover? How big is it?

Or how small?

Answers to these questions determine the relationship between growth and profitability.

Simply put, if you cover a small delivery, you risk expansion over profit.

If you plan overextend, you risk profit margins versus growth.

Technically, there has to be a balance.

It’s better to plan small until you are certain the delivery won’t affect your bottom line.

The smaller the delivery zones, the smaller the delivery market.

At the same time, the delivery time window is shorter.

So, it takes less time to fulfil an order with a much higher success rate.

Reducing your delivery to the local last-mile (5-10 kilometres) increases the route density while minimizing delays. And demand is high, you can expect order volumes to remain high, as well.

This also raises the speed of delivery. You can get an edge over competitors with fast fulfilment options, like same-day delivery.

From there, you can use different delivery tactics to grow your operations and scale it over time.

When demand exceeds your capacity in the last-mile. Volumes increase every day. Contactless delivery is gaining momentum.

Two things remain certain: there are challenges and there are possibilities.

How well you overcome delivery problems and take advantage of coming opportunities will define your operations and impact its success.

And while you can’t go back to business as usual, there are measures you can take to keep your delivery afloat.

Payroll is a big chunk of the overall costs of managing deliveries.

And for your operation, that means team performance is closely tied to cost-effectiveness and efficiency.

At the same time, it is difficult to measure it. Albeit different teams and team members perform different tasks at different rates, the lack of insight can lead to a lack of output.

So, visibility and oversight are key for tracking and managing their performance.

But too much active oversight can put pressure on your teams. The pressure to perform in combination with direct control can result in interruptions, frustration, and even burnout.

Ultimately, this hurts performance and causes a decline in output.

So, while it’s necessary to track output, you have to monitor it from afar both at the individual and organizational levels.

The solution is to find a balance between control and supervision.

Deciding to centralize or not to centralize delivery operations is the first step.

Centralization can help consolidate all of your assets to ensure greater control over your delivery. On the other hand, decentralization can give your teams more independence to perform tasks. A middle ground might be the best action plan.

Similarly, it’s important to automate your operations. But this begs the question: Are you still planning manually your delivery?

If you are, now is the time to stop. It’s time to choose delivery management software.

This type of technology makes it simple to monitor all your operations from one position. It gives you a total overview of performance at the office, as well as the field, and in real-time.

This makes it possible to track and evaluate performance without putting pressure on your staff or interfering with their work. And because you automate specific tasks, it also makes better use of each persons’ unique talents.

For example, a route planner can focus more of his time on building better delivery strategies, and less time mapping routes with multiple stops.

That can lead to a better quality of work, better work conditions, and less inconsistency and inertia in output, as well.

Delivery accuracy is a major concern for fulfilment.

It is closely linked to order accuracy or the perfect order metric.

Monitoring key metrics in delivery like this one allows you to identify inaccuracies in the delivery process.

It lets you keep track of failed deliveries, mistaken orders, returns, and damaged goods, and determines the success rate of your delivery teams.

These inaccuracies can happen across the delivery lifecycle, and at any point during the life cycle. That’s why identifying them involves monitoring each stage of the process:

A good workaround to this problem is to encourage drivers to submit reports using electronic proof of delivery.

Drivers can submit reports with an app on their phone. The report automatically uploads to the main dashboard via cloud-technology. Dispatchers and operation managers can immediately access the information to determine order accuracy.

At the same time, ePOD lets customers leave feedback and rate drivers. That confirms or denies driver reports, as a system of checks and balances. And this ensures that if mistakes happen, they are transparent and easily resolved.

The digital transformation has changed how many companies manage their deliveries.

Unlike before, fewer and fewer organizations rely on simple pen and paper to manually plan routes. Disconnected apps and legacy solutions are also out.

So, as more and more companies are adopting a cloud-first approach to delivery logistics, it is now the standard for managing operations.

Companies that don’t follow the latest delivery ma risk being left behind. Others cannot simply find that keeping up with the demands of the modern last mile is impossible without software.

But these powerful solutions are more than a necessity. They are also incredibly good for business.

Solutions like delivery management software can automate the entire delivery process, from the first to the last mile.

That’s because these systems use different modules to tackle some of the biggest delivery challenges like:

With such advanced features, it is possible to manage all operations from one centralized platform. Not to mention, minimize costs while raising output and performance at the same time.

And the best part is that you can fix any mistake with a click of a button.

Unless you take care of these mistakes, they can happen time, and time again. So, it’s vital to use these solutions to fix them as soon as possible.

But there is more.

To truly root out these problems, you have to learn from them. All of it counts for nothing if you end up letting them happen in the future.

Offering flexible delivery options, maintaining quality, saving costs, using delivery management software to automate the process, and focusing on customer experience has a positive impact on your operations.

So, going forward, apply these solutions at every level of your organization.

Now, it’s your turn. What’s the next step you will take?

If it’s automation, we have a software solution for you.

In this article, we reveal how delivery management software can help you to win more customers, handle more orders, and make more money.

This is a complete guide to last-mile delivery. Learn: What is last-mile delivery? How it works? How to improve your last-mile operations? +more

Learn how to fast track your delivery with this step-by-step guide. And see how you can make it much faster, while providing the best delivery...

Be the first to know when new articles are released. eLogii has a market-leading blog and resources centre designed specifically to help business across countless distribution and field-services sub sectors worldwide to succeed with actionable content and tips.