4 Best Field Service Mobile Apps for Your Mobile Workforce

We’ve put together a list of the top 4 field service mobile apps, including: eLogii, Jobber, ServiceTitan and Dynamics 365. So you can choose the...

Home > Blog > Why Field Service Schedules Fail in Real-World Conditions

Field ServiceFind out why field service schedules fail in real-world conditions, and how execution-focused systems can help you stay efficient despite the disruptions.

As important as planning is, your field service schedules will fail if you don't focus on what’s actually going on in the real world.

If you’re managing complex field operations with 50+ technicians, you already know this.

But why does this happen?

Why do field service schedules break down when you apply them to real-world situations?

(Despite the fact that you employ experienced planners who use the latest scheduling technology.)

The answer is: EXECUTION.

Scattered optimization activities don’t translate to proven time savings, higher output, or revenue growth unless you align them to the activities in the field.

Optimized schedules ≠ optimized field operations ≠ effective field services.

To get real results, your whole team needs to start planning schedules proactively to include the inevitable disruptions that will occur in the field.

In this guide, we explain exactly the biggest challenges to implementing field service schedules and how to overcome them. By the end, you’ll know how to roll out job schedules that don't just survive the morning, but the entire day.

Here’s everything you’ll find in this guide:

Static schedules break down fast. Even well-optimized plans fail by mid-morning due to real-world disruptions like sick technicians, overruns, cancellations, and reactive jobs.

The problem isn’t planning quality—it’s execution. Traditional scheduling tools are designed to create plans, not to manage continuous change once work is in motion.

Operational complexity exposes flawed assumptions. Inaccurate job durations, shifting priorities, skill mismatches, and routing inefficiencies compound throughout the day.

More planners and better visibility don’t solve it. Adding headcount or dashboards increases awareness but doesn’t provide real-time control or decision automation.

High-maturity teams focus on execution layers. Leading organizations use systems that dynamically rebalance work in real time, treating schedules as a baseline—not a rigid contract.

Every field service organisation recognises the pattern:

You build the schedule carefully for tomorrow. Field service job scheduling is applied and jobs are assigned to technicians and engineers. You optimize routes. SLAs appear achievable. On paper, everything works. Then it happens…

By 10:30 AM, your plan is broken.

A technician calls in sick. A reactive job escalates to critical. A customer doesn’t show up on site. A job runs longer than you estimated. Traffic spikes. A part is missing. A depot manager reprioritises work based on a contract penalty. The field work scheduling that looked logical at 7:00 AM isn’t relevant anymore.

For many field service leaders, this scenario is usually described as normal:

“It sounds daunting to most, but this is our constant, and we’re used to it, so it’s normal to face schedule changes.”

You accept that schedules change during the day. Planners expect disruption. Dispatch teams adapt. Technicians and field engineers improvise.

But this normalization hides a deeper issue.

If schedules fail every day, the problem isn’t poor discipline or weak planning. It’s the static field service scheduling. As a concept, static schedules can’t survive real-world operational complexity.

Field service operations with 50, 100, or 500+ technicians don’t operate in controlled environments. You manage dynamic systems:

Service demand fluctuates

Capacity shifts

Job durations vary

Geography matters

Compliance windows close

SLAs trigger penalties

Customers cancel, reschedule, or escalate

Yet most approaches to scheduling assume relative stability. You assume start times hold, job durations are predictable, and technicians progress linearly through the day.

They DON’T.

The result is constant re-scheduling. Planners troubleshoot instead of planning. Dispatchers manually intervene. Technicians make on-site decisions that optimize their day but reduce operation-wide performance.

The industry responds by making more detailed schedules, and prioritizing the most important calls first. This feels sensible. In practice, it’s reactive triage, not operational control.

So, the real question isn’t why schedules change during the day. The real question is why do you still rely on planning to solve complex workforce scheduling problems and field service management challenges.

Field service scheduling was originally designed as a planning function. At its core, field service job scheduling answers a limited set of questions:

Which jobs need to be done?

Which technicians are available?

Which skills are required for the job?

What is the optimal assignment based on (cost, time, and constraints)?

For planned maintenance, this works well. Planned preventive maintenance tasks (PPM) are known in advance. Time windows are broad. Variability is limited. And technicians and engineers have to follow repeatable patterns.

Field service scheduling systems excel at creating these types of plans. You can easily use these tools to allocate resources efficiently, reduce travel where possible, and balance workloads.

But there is an underlying problem to this. All of these tools operate under the assumptions that:

Job durations are accurate

Start times are predictable

Technicians follow planned routes

Service demand doesn’t change

Exceptions are rare

These assumptions fall through the moment reactive work enters the system (unplanned service requests, emergency calls, breakdown maintenance). This is the typical field service scheduling problem.

In mixed operations where field service organizations combine PPM and reactive jobs (which is most businesses), service problems quickly multiply.

Planned work is fitted around expected break-fix demand. Buffers are added. Rules are layered on top of rules. The schedule becomes a best guess.

This isn’t a failure of your planners or the scheduling algorithms in the tools that they use. It’s a mismatch between purpose and operational reality.

Field service scheduling tools are optimizers, not control systems.

They generate a plan but don’t allow you to manage execution once reality deviates from that plan. This is what leads to workforce scheduling optimization problems.

In small teams, human oversight fills the gap. A dispatcher knows the technicians personally, and can make adjustments informally based on experience and operational knowledge.

But at scale (across multiple regions, starting points, contracts, and compliance requirements), this approach collapses. This is what creates your recurring job scheduling problems.

Over the years, we’ve encountered an alarming amount of scheduling problem examples. Most (if not all) have to do with the size, scale, and complexity of the field service within which those organizations operate.

And you’re probably aware of most of them:

Static schedules assume jobs start when you plan them. In reality, start times drift constantly.

This creates a common staff scheduling problem:

A technician finishes early and arrives too soon on site for his next job. The customer isn’t ready or isn’t on location. Or the previous job overruns and delays all of the jobs downstream.

When this happens, start times become estimates, not commitments. And planned ETAs don’t materialize, while planners and customers are still counting on them.

Even mature organisations struggle with accurate job duration estimates. This is a frequent field service scheduling problem.

Reactive work varies widely from job to job. In most cases, emergency service calls don’t provide you with accurate information about conditions.

These job requirements stay unknown until your field technician arrives on site. But there, he might encounter site access issues and additional faults that the customer hasn’t mentioned.

In these situations, allocated service time overruns to the next job. And when one job is overrun by 30 minutes, every subsequent job is affected. And the job scheduling optimization constraint that you wanted to mitigate breaks down.

Same-day changes aren’t isolated events. They are inherent and create staff scheduling problems that impact service execution and efficiency down the line:

Cancelled jobs create idle time

High-priority calls displaces planned work

Swapping technicians creates travel inefficiencies

To fix this, planners have to troubleshoot issues and make adjustments to the schedule. But each manual adjustment introduces friction elsewhere in the system, which makes your workforce scheduling problem worse.

Once you manually adjust schedules, route optimization breaks down, as well. For most tools, this is an issue because they lack the capabilities to dynamically adjust routes in real time.

This leaves your field technicians zigzagging between jobs. As a result, drive-time increases, performance falls, and cost-to-serve skyrockets.

All the while, your optimal job scheduling is lost.

Under pressure from reactive work, planners and dispatchers typically prioritise speed over fit:

The nearest technician is assigned to the emergency job, even if their skills don’t match the work that’s required. The result:

First-time fix rates drop and repeat visits increase.

Short-term recovery creates long-term inefficiency and contributes to your ongoing scheduling problems.

Most scheduling systems, including the ones you use, lack real-time execution awareness.

You don’t know precisely where your technicians are. You don’t understand job progress beyond manual updates. And you can’t proactively rebalance work as conditions change in the field.

By the time issues are visible, it’s too late to optimize, which causes persistent field service management challenges for you across the entire operation.

By mid-morning, planners and dispatchers shift from proactive planning to reactive control. The day becomes a series of interventions that demonstrates the workforce scheduling problem in action, and sentences you’re probably all too familiar with:

Reassign this job!

Delay that visit!

Call the customer!

Swap technicians!

Push work to tomorrow!

Each decision is locally rational. Collectively, each one lowers operational performance across your team:

Technicians and engineers feel the impact first. They lose confidence in schedules. They stop trusting start times and build personal buffers. They optimize their own routes.

Managers lose predictability. SLAs become harder to forecast. Overtime increases. Customer satisfaction becomes volatile.

Leaders see the symptoms by mid-morning: rising cost-to-serve, missed SLAs and customer commitments, planner burnout.

The root cause is rarely addressed, while scheduling problems accumulate daily.

When schedules fail, organizations typically respond by hiring more planners or dispatchers. But that also means more people to manage complexity and ongoing field service problems.

In practice, this does provide short-term relief. More hands can process more exceptions, phones get answered faster, and emergencies are resolved. The schedule is pointless, but that’s normal.

The hard truth that most field service businesses fail to understand is that complexity grows faster than headcount.

Each new planner introduces coordination overhead and costs rise without structural improvement. In a more practical sense, decision-making fragments and consistency fails, while your entire operation becomes dependent on heroics from individual planners and technicians.

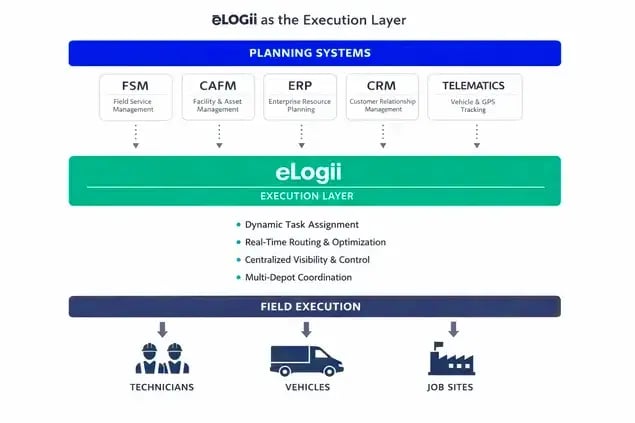

Many field service organisations, like yours, invest in tools to handle field service management challenges. Tools including:

Field service management (FSM)

Computer assisted facility management (CAFM)

Enterprise resource planning (ERP)

Customer relationship management (CRM)

Telematics systems

All of these platforms are good at providing you with intelligent dashboards, accurate ETAs, GPS tracking, mobile updates, access to field data, and more. And investing in them improves operational awareness through visibility.

However, what it doesn’t do is give you operational control to resolve the workforce scheduling problems.

Operational visibility can only tell you what is happening. It doesn’t decide what should happen next. Because the reality of FSM, CAFM, ERP, CRM, and telematics is that they’re systems of record not systems of execution.

And without an execution layer, data becomes informational rather than operational. Your planners still have to make manual decisions under pressure, which results in latency and efficiency loss.

Based on this system, you’re able to observe failure more clearly. But the schedule still fails.

The failure of field service schedules isn’t technical, it’s conceptual:

Scheduling (planning discipline) ≠ Execution (operational discipline).

Confusing the two creates systemic fragility and recurring scheduling problems.

A schedule answers the question: Given what we know now, what is the best plan?

Execution answers a different question: Given what is actually happening, how do we achieve the objective?

In complex field operations, these questions diverge quickly, creating a classic workforce scheduling optimization problem.

Once the day starts, reality begins to overturn your assumptions. Job durations drift. Priorities shift. Capacity changes. Geography imposes friction. Compliance windows tighten. Customers introduce uncertainty.

A planning system can’t continuously reconcile these forces, which results in ongoing field service scheduling problems.

Most scheduling systems are also fundamentally batch-oriented. They optimize at a point in time. They assume the output will follow. When conditions change, you’re required to manually re-plan, re-schedule, or implement partial overrides.

On the other hand:

Execution is continuous. Optimal job scheduling requires constant recalibration and an execution system continuously evaluates trade-offs:

SLA risk vs. drive time

Skill match vs. response speed

Technician utilisation vs. operational resilience

A system built for execution reallocates work dynamically. It re-optimizes routes as conditions change, and enforces priorities consistently across regions and depots.

When organisations attempt to run execution through a planning tool, your service planners are the execution layer. They bridge gaps manually, resulting in persistent scheduling problems.

This approach might function at a small scale. But it doesn’t scale across 50+ technicians, multiple depots, mixed work types, and various contractual obligations.

High-maturity field service organisations accept that you can’t eliminate real-world conditions or their variability. You HAVE TO manage them.

They don’t treat disruption as a failure of planning. Instead, they treat it as a constant input into their operating model. This allows them to address the field service problems proactively rather than reactively.

Instead of aiming for perfect schedules, they aim for stable execution under imperfect conditions, which solves workforce scheduling problems in real time.

Execution is the primary control layer. Scheduling becomes a baseline, not a contract you have to follow at all cost.

In such a system:

Automation replaces manual dispatching

Buffers are explicit, visible, and dynamic

Uncertainty is reduced before work hits the field

Routes are dynamically and continuously optimized

Roles and metrics reinforce the model

All of this directly addresses field service management challenges and ensures optimal job scheduling despite the complexity of your operation.

eLogii is designed for the part of the operation where most systems lose effectiveness:

eLogii bridges the gap between plan and reality, which is the core of most field service scheduling problems.

It doesn’t replace strategic planning, workforce management, or long-term capacity modelling. It doesn’t replace existing technology, FSM, CAFM, ERP, CRM, and telematics. All of those functions remain essential.

eLogii sits at the execution layer: The point at which work is actually delivered in the field and conditions are changing minute by minute.

The software continuously evaluates technician locations, job progress, new demand, service cancellations, overruns, priorities, and constraints. Based on this, it dynamically re-optimizes routes and assignments across the network, mitigating constraints and field operation optimization.

This allows you to respond to disruption systemically rather than manually, tackling workforce scheduling optimization problems directly:

Planners and dispatchers are relieved from moving individual jobs reactively. The system recalculates optimal outcomes, balancing travel time, skills, utilisation, and SLA risk in real time. Field service problems are resolved more efficiently.

Field technicians and engineers receive updated routes that geographically make sense. Planned work is protected where possible. Reactive work is absorbed without cascading failure. Customer commitments are adjusted with intent rather than urgency.

Managers and stakeholders gain a control surface for execution. Trade-offs are explicit and performance is shaped during the day, not explained after it. This addresses challenges in field service management without relying on perfect data or perfect plans.

The goal isn’t to eliminate disruption or variability. It’s to run the operation effectively despite it.

But this approach isn’t for everyone.

SMBs and small field teams can handle disruptions to their field service schedules if you simply change the mindset to execution-led planning. Schedule changes will happen, but we have a system in place that can effectively handle anything that happens in the field.

eLogii is a good fit for field service enterprises and large organizations that want to grow further, while scaling operational control and efficiency as they grow.

If you employ 50+ field technicians or engineers, handle 100+ service jobs daily, across several service zones or multiple regions, with multiple starting points, facilities, and depots, having an execution layer in place isn’t optional for you. It’s inevitable.

|

eLogii is for you |

eLogii isn’t for you |

|

Organisations with 50+ field technicians or engineers |

Small teams with low job variability |

|

Multi-region, multi-depot operations |

Single-location or single-route operations |

|

Mixed planned maintenance and reactive work |

Purely planned, low-urgency work |

|

Environments with SLAs, penalties, or compliance windows |

Informal service models with flexible commitments |

|

Leaders seeking scale without adding planner headcount |

Teams comfortable relying on manual dispatch and heroics |

Field service schedules fail because you expect them to do a job they were never designed to do. Planning and execution are distinct capabilities, and you shouldn’t treat them as the same.

If you adopt an execution-layer approach to how you schedule field services, you’ll gain control, resilience, and scale.

The next step isn’t to plan a better schedule. It’s to better manage execution, so you can optimize workforce scheduling and tackle scheduling problems effectively, as they appear.

If you’re interested in learning more about eLogii and how it layers execution on your existing field service management system, let’s talk.

We’ve put together a list of the top 4 field service mobile apps, including: eLogii, Jobber, ServiceTitan and Dynamics 365. So you can choose the...

We reveal our pick of the best field service CRM software: Salesforce, HubSpot, Pipedrive, and Zoho, with full reviews and how to integrate with...

In this guide, we compare five leading field service management software solutions: Simpro, eLogii, Salesforce Field Service, Connecteam, and Jobber.

Be the first to know when new articles are released. eLogii has a market-leading blog and resources centre designed specifically to help business across countless distribution and field-services sub sectors worldwide to succeed with actionable content and tips.