Food warehouses always struggle with time. Food items such as dairy and frozen products can spoil quickly if not stored properly. Product relocation requires careful planning. Supply chain problems happen a lot. Time is a big issue for food warehouses.

Working in food warehousing is tough, but it's also very fulfilling. You play a crucial role as a protector of the food supply chain. It means ensuring essential sustenance reaches the community.

Luckily, you can make your important job simpler by improving how you manage your supply chain.

Here's how to make storing food easier and manage time better by optimizing the supply chain:

Improving Food Warehousing in 6 Steps

Explore a simple 6-step approach businesses can use to improve food warehousing and increase efficiency. This process aims to improve financial performance as well.

Step#1: Consider the End Results When You Start Food Warehousing

In "The 7 Habits of Highly Effective People," Stephen Covey suggests connecting tasks with larger objectives. For food warehouses, starting with the end goal in mind is essential for optimizing the supply chain and getting work done on time.

The most essential moment in your product's journey is when it reaches the customer. Every step in your supply chain, from start to finish, should be improved. Remember that customers are the reason your business makes money. Without customers, there is no business. Yet. if you can keep them returning, you'll establish a foundation for long-term success.

When you begin with the customer and move backward, it becomes clear that the delivery area determines the kind of vehicle you need. You want to avoid spoilage of goods during transportation to the customer. Consider this scenario: You can use an insulated bag for a short drive to deliver the cheese securely. Yet, if the cheese is in transit for eight hours, it creates a cold chain logistics challenge. In this case, you'll need a refrigerated truck. Thus, it's crucial to determine the destination before selecting the appropriate delivery vehicle.

Likewise, packing must prevent spills or cross-contamination in the last mile delivery phase. How do you decide on the specific packaging required? Consider the truck or vehicle they'll use, whether it's a flatbed or has food storage racks. To plan each stage in your food logistics, think about what comes next. Work backward to find the best strategies for each step.

Step #2: Improve the Efficiency of Final-Mile Delivery With eLogi

Let's explore a more streamlined approach to supply chain optimization with software.

eLogii is a software solution that improves the efficiency of your supply chain's last mile. It starts by prioritizing the customer experience.

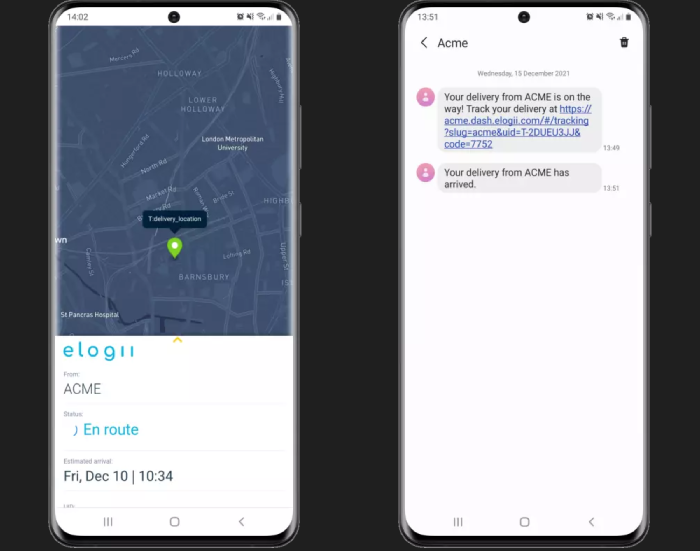

Customers can now customize their notifications, which will be delivered automatically upon order shipment. Your customers will get a live tracking link to see when their order will arrive. Providing real-time notifications to customers can enhance their satisfaction. They make it more likely that customers are home for delivery. It reduces service calls by 70%. Plus, you get a top-notch customer service rating.

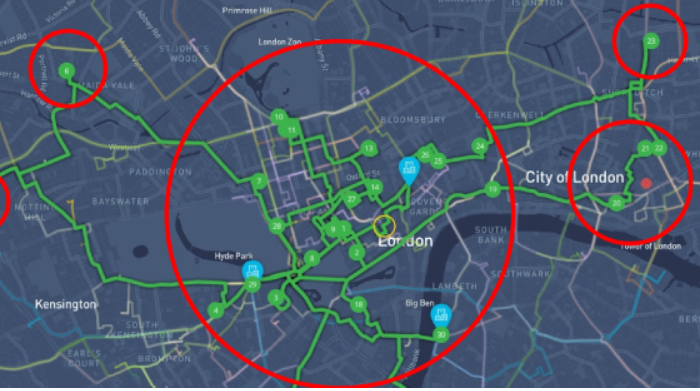

Dispatchers can easily route and schedule thousands of deliveries with the help of eLogii, a robust solution. All this, up to five weeks ahead in a matter of seconds. Performing these lightning-fast calculations manually is a rare skill. If you find someone who can do this as quickly, we'd love to meet them! For those of us who aren't superhumans, robust software becomes an invaluable tool. With eLogii, you can simply upload delivery orders from a spreadsheet. Then, add delivery windows, and specify driver/vehicle constraints (like a refrigerated truck). Click on "Plan routes," and you're good to go!

eLogii offers valuable help to food businesses. It helps them to simplify the delivery process and optimize operations. For instance, it enables seamless route and schedule planning for thousands of deliveries up to five weeks in advance. This, in turn, ensures efficient product distribution. By automating the process, eLogii eliminates the need for time-consuming manual calculations. It, thus provides a significant time-saving advantage.

Real-time tracking keeps customers informed about their order's location, enhancing their experience. Automated scheduling and customizable notifications contribute to timely deliveries and customer satisfaction. Additionally, eLogii aids in reducing operational costs by optimizing resource use. It also supports scalability for growing food businesses. Overall, eLogii helps to streamline the last mile of delivery operations, improving efficiency and customer service for food businesses.

Step #3: Track Inventory in Real-Time

Real-time visibility plays a vital role in optimizing food warehouses and managing inventory effectively. The ability to locate items eliminates time wasted searching. Knowing the upcoming end dates of food products, whether in the next week or month, facilitates proactive planning. Efficient inventory management relies on swiftly retrieving information. It underscores the importance of real-time tracking for optimal food warehouse operations.

Traceability is crucial for streamlining food logistics. It encompasses the journey from production to sale. Making it simpler to maintain, real-time knowledge of your product locations is key in this process. Namely, a Warehouse Management system (WMS) is software for real-time visibility in your warehouse. It replaces paperwork and speeds up operations in your food distribution center. It also means simplifying warehouse audits. With a WMS, scheduling and monitoring audits become more manageable.

When orders arrive, pickers get pick lists on handheld or wearable devices. These guides them to items and the order sequence in your facility. The cool part? WMS like Logiwa or Infoplus Commerce can connect with route optimization software (e.g., eLogii). It helps with real-time visibility from your warehouse to your customer's doorstep.

#4 Secure Your Inventory in the Food-Grade Warehouse

Once you've made your food warehouse operations smoother, it's time to delve deeper. If the storage for food grade isn't secure, your food becomes prone to spoiling. The result is potential food waste and safety concerns. Accidents can happen, but there are steps you can take to reduce risks, and these tools can assist:

- Programmable thermostats help you control the temperature in different sections of your warehouse. Tailor the settings for peak times, particularly around loading or receiving docks. This is where external air may affect conditions. For cold storage facilities, tracking the temperature in these storage areas is crucial.

- Occupancy sensors play a key role in adjusting lighting within your facility. Configure lights to turn off or dim in unoccupied areas. This will prevent excessive temperature rises and reduce electricity costs. Additionally, linking occupancy sensors to thermostats aids in maintaining optimal temperature control.

- Pheromone traps are a robust defense against common pests found in cold and dry storage. These pests are usually moths and beetles. In this case, vigilant pest control is crucial. It helps you maintain sanitation and quality in food storage warehouses. Pheromone traps emerge as effective tools in this ongoing effort.

Detecting issues early or averting them entirely epitomizes optimal efficiency. To avoid dealing with heaps of spoiled food, you should prevent spoilage in the first place. Thermostats, sensors, and pheromone traps collectively contribute to steering clear of disasters. Additionally, make sure to focus on sanitation with a well-structured schedule.

#5 Optimize Employee Training and Schedule Coordination

Food warehousing workers must follow FDA food handling rules. You're in charge of their training, but it doesn't have to be boring. You can use Eduflow software to make interactive modules. This streamlines the employee onboarding process.

Important Note: Training for federally regulated certifications in the food industry, like Preventive Controls Qualified Individual (PCQI), must meet FSMA compliance. A qualified instructor is essential for these certifications. Ensure FSMA adherence by having qualified instructors lead the training.

PARiM employee scheduling software enhances day-to-day operations. Efficiently handle personnel planning using one platform. Manage payroll reporting, timesheets, uniform assignments, and vacation days without effort with PARiM.

Pro advice: To schedule drivers in food warehouses with their delivery teams, use eLogii.

#6 Use Analytics for Adapting Food Grade Warehousing

All businesses can improve. Identifying broader inefficiencies can be challenging, especially in food service. Software analytics provide clear metrics and insights for smart adjustments. This is also true when it comes to faster operations and successful scaling.

Take Crocus as an example. By employing eLogii's analytics with current and historic metrics, they achieved remarkable results. Crocus realized a 65% improvement in driver productivity. They also reduced planning time by 75% and doubled customer service effectiveness. The analytics provided actionable insights into their business and operations. This, in turn, enabled them to make strategic adjustments.

Many software, like WMS and employee scheduling tools, include analytics. They help pinpoint wasted spending areas and determine what's necessary for business expansion. Start with analytics for effective decision-making.

Food Warehousing FAQs

- What is food warehousing? Food warehousing involves storing food products before selling or distributing them. This process spans the food supply chain, offering storage, handling, and related services.

- How is food stored in warehouses? Warehouses use various methods to store food products. It includes dry and freezer storage, tailored to the specific needs of each food item.

- Why is food warehousing vital? Proper food warehousing helps cut the risk of spoilage or contamination. It also ensures the timely delivery of products and optimizes food distribution in the food industry.