How to Cut Costs of Wholesale Construction Materials Delivery

Learn how to reduce costs of your wholesale construction materials delivery by using route optimization software to increase efficiency.

Home > Blog > Delivery Management Software for Construction

ConstructionExplore how you can use delivery management software in construction: for delivering construction materials and managing the logistics on projects.

Today, you’ll see how you can use delivery management software in the construction industry.

So if you want to:

Deliver construction materials faster and more efficiently.

Better manage the logistics on construction projects.

Make operations more cost-effective and sustainable.

Then, you’ll enjoy all the ways this software can help you.

Let’s dive in.

Delivery management software is a digital solution designed for managing delivery logistics. It enables you to plan, manage, and optimize the entire delivery process.

With this type of tool, you can do this from the first to the last mile of delivery. And across the supply chain, right down to how you plan pick-ups and drop-offs.

That’s why it’s often referred to as an end-to-end solution.

And typically, yes - this software is used for delivery and distribution.

But it’s also used by third-party logistics providers (3PLs) and field service operations.

That’s why you can use it to better organize how you transport men, materials, and equipment.

Which is necessary when you want to automate the way you handle logistics.

Or optimize distribution and transportation. (Regardless of the industry you’re in)

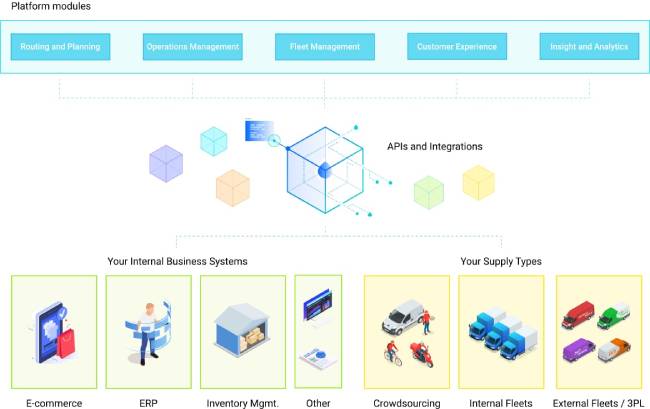

Delivery management software is a modulated platform.

Different modules correspond to different logistics activities.

You can use the software to manage:

All of these modules are connected. But you can use each one autonomously, as well.

The software also works using cloud computing and technology.

That’s why it’s a software as a service (SaaS) solution.

Adopting the cloud-first approach to managing delivery logistics also means you can connect it to a wider ecosystem.

You can use APIs to integrate the software with other internal business systems.

Including:

But this also enables you to use the delivery software with various supply types.

So, you can use it with internal and external delivery fleets.

But also 3PLs and crowdsourcing models.

On average, SaaS delivery management software costs $182.35 per month.

That makes it far less expensive to use than legacy systems.

Instead of paying to license the software, you pay a fee to use it.

This means it’s up to the provider to host, update, and maintain the software.

(Like a service)

So, while making a one-time payment seems more cost-effective, it isn’t.

To be clear:

The delivery management software market is saturated with many options.

So, if you want to choose the best delivery software, you’ll have to do some research.

Luckily, we did it for you in our guide on the cost of delivery management software.

Now, it’s time to get specific.

In this part of the article, you’ll see EXACTLY how delivery management software helps construction companies.

(Regardless of whether you distribute construction materials or carry out complete projects as a contractor)

Here’s what the software allows you to do:

Delivery management software is a construction logistics solution.

It enables you to digitally transform their entire operations.

And that allows you to automate how you:

This means you can use the software for distribution and construction.

That’s because you can use the various software modules to plan and manage:

And that means you cover the entire process throughout the ecosystem using just one tool.

Be it supply chains, forward, or reverse logistics.

How you transport men, materials, and equipment to destinations is a critical problem for companies in construction.

First, there are the roads.

You need to consider what types of roads cumbersome construction vehicles will have to cross to reach their destinations.

Urban areas often have narrow streets, overpasses, and pedestrian areas.

Here, it’s usually impossible for large vehicles to pass to reach drop-offs.

Away from cities, country roads may be small, but also poorly maintained.

This means that heavy-duty vehicles could get stuck or cause damage.

This is why local councils have regulations in place that limit what vehicles can move on which roads.

Then, there are the costs of transportation. Which you need to keep to a minimum.

So, you really HAVE TO plan optimal routes for drivers.

And that’s where delivery management software comes in:

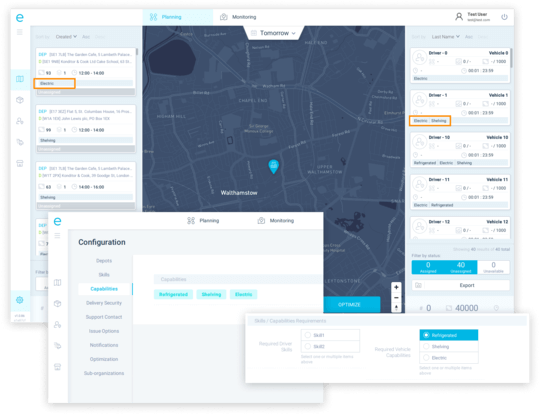

Route optimization is one of the main capabilities of the software.

You can use it to map routes with multiple stops for all vehicles based on relevant constraints.

Best of all, you do it automatically, with a click of a button:

So you can plan routes regardless of:

And the system will always calculate the best route based on fuel efficiency, low costs, and speed.

This means you’ll also be able to plan better delivery schedules…

Scheduling and route optimization are linked.

You can’t have good routes without tight schedules.

So when using delivery software to plan schedules, you can take into account:

This ensures that the people, machinery, and materials reach locations on time.

But it also significantly minimizes congestion at the sites. Which tend to have limited space, and can’t accommodate all incoming vehicles at the same time.

Likewise, delivery management software makes these schedules transparent.

You don’t have to print out schedules for drivers or dispatch them manually.

The software has an integrated delivery driver app.

Once you finish planning the routes and schedules on the main control panel, they’re automatically uploaded to the application.

So, drivers can see where and when they need to pick up their passengers or shipments.

But also:

This means you can coordinate the entire operation from one central location, with no need for any intervention once you’ve locked in the schedule or adjusted it.

It’s easy to forget that the supply chain is a critical part of how you distribute your resources to contractors and construction sites.

And the two biggest problems are:

If you don’t order enough materials and equipment, you won’t be able to deliver them to customers.

If you order too many materials and equipment, you can start losing money on idle resources that are taking valuable storage space.

What’s the solution?

Track order frequency and availability.

And the only way to do that accurately is to automate how you manage the supply chain.

What delivery management platforms can do for you here is keep track of deliveries and bookings.

With a clear overview of day-to-day schedules, you can see how many materials are leaving your warehouses.

You can also clearly review return times of men and equipment from a particular destination.

And when you know how long that is, you can align order frequency with availability.

So you can always meet the demands of your customers (even when demand exceeds your capacity).

But you also cut down on waste and have greater control over spending, as well.

Typically, you’re never the only distributor or contractor on a construction project.

The problems are the narrow arrival windows.

The other problem is the limited space at the site.

This means that you’ll have to coordinate how you manage your fleet not just within your team, but also with other suppliers if you want to avoid congestion at the drop-off zone.

Even if you’re delivering materials to multiple sites, customers, or contractors, you’ll still want to know what your drivers are doing and where they are.

So, you’ll want to have visibility over last-mile delivery operations.

And that’s exactly what delivery management software can give you.

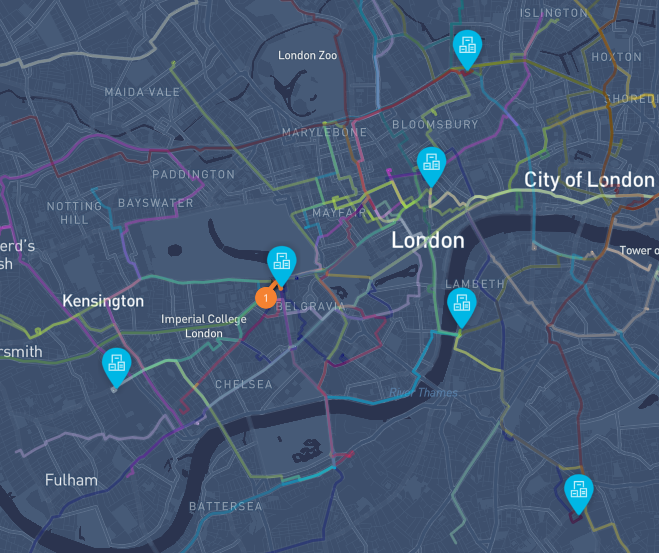

Because it has integrated geocoding, you can connect the software to any onboard telematics system, GPS, or device geotargeting.

This means that you can gain real-time visibility over the entire fleet on a digital map:

So you can monitor each driver and their performance as they move across the map (from destination to destination).

Construction requires a lot of logistical planning and manpower.

Delivering construction materials requires men and equipment to load and unload them.

And if you transport heavy-duty construction equipment, it usually arrives in parts.

So you need to assemble them at off-site locations using hoists and forklifts.

All of this means that any software has to have integrated material handling capabilities.

Even if you think that delivery management software is suited for food delivery, you can actually use it for this as well.

How?

Simple: all the tasks you create are completely customizable.

You can add notes, assign personnel and equipment to each specific task.

And because you set the priority of all of them, you can rest assured that they’ll arrive in the order you need them for unloading or assembly.

All logistics planners have to do is put the puzzle together.

The construction industry is heavily regulated.

It sometimes feels like there are a dozen compliance requirements you have to meet.

From local and national, through environmental, to health and safety regulations, it can be a logistical nightmare to keep track of them.

Delivery management software can help your business there, as well.

First, you plan the entire process on one centralized management system.

That gives you complete control over operations.

For example: site activities, work hours, or worker breaks and shifts.

Then, you can make notes for each task.

This means you can easily align national, federal, and local requirements for each task.

So your employees can read the task instructions and prepare documents or equipment, depending on the jurisdiction of the site.

Best of all you can prepare all the digital documents while you’re planning the routes.

You can even upload them to the platform and app when the drivers have already left for their routes.

(In case you miss any of them)

No room for human error = No break of compliance

Documentation, forms, reports, assessments, environmental and safety requirements…

You’ll agree, there’s a lot of paperwork you need to finish a project.

(Regardless of whether you only distribute construction materials or you’re a contractor)

To be clear:

Delivery software can’t help you to keep up to date with compliance requirements.

But what it can do is help you to easily access these documents in the field.

You can attach specific documents to the corresponding task.

For example, you can add a .pdf approval to use city roads to deliver construction material in urban areas.

If a driver comes across an inspector, they can access the document via the delivery app on their Android or iPhone.

If they’re delivering the materials to a contractor, they can use the electronic proof of delivery (ePOD) to confirm their arrival at a site.

And because it operates on the cloud, the system stores historical data.

So once you need to use the same document, all you have to do is reattach it to the new task.

Delivery management software operates using cloud technology.

Because of that, it collects a lot of data.

And all of that data is stored on the cloud.

So the information you upload, input, and generate by running your business is automatically saved to the platform.

But to use big data, you have to analyze it.

That’s why the software has a module that enables you to measure key performance metrics in delivery logistics (KPIs).

Analyzing KPIs over time, like cost per delivery or on-time drop-off, gives an accurate insight into the productivity of your teams.

It also lets you discover and identify operational waste.

So once you pinpoint problems, you can fix them.

On the other hand, you can also uncover improvement opportunities. And then, use tactics to grow your delivery operations.

And because you’re always collecting data, you can continuously optimize operations to scale.

Without any surprise, delivery management software is the future of delivery.

It unites all the different aspects of delivery logistics and puts it under the same roof.

Its uses are vast which is possible because of cloud computing.

These uses are also available to almost any company despite its size.

There is no such thing as one size fits all.

But it is also adaptable and customizable to fit all needs.

So it benefits your company in more ways than one:

To begin with:

Delivery management software saves you money.

How?

On the one hand, it optimizes your operations.

Controlling everything with a centralized system helps you to uncover operational waste.

This allows you to set up strategies to reduce that waste.

And in doing so, improve the performance of your teams.

At the same time, it means you can find new opportunities to raise workload capacity.

So…

As you cut back on operational expenditure, you also increase output.

And that translates into:

Fewer costs.

Greater efficiency.

And more revenue for your organization.

To be clear:

You’ll need to spend time manually setting up your operations once you subscribe to a platform.

Among other things, you’ll have to:

But once you do all that, it takes less time to plan day-to-day operations.

And that’s because:

Delivery management software automates the whole planning process.

First, you can use one of two ways to add tasks, booking, and deliveries:

You can either upload them in bulk from a file.

Or you integrate the system with an OMS or booking software, and let it automatically import order requests from there.

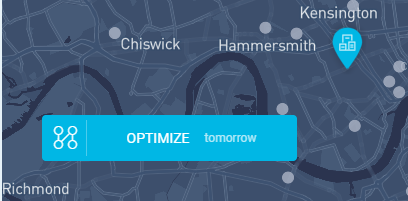

Once all of the order data is in the system, you have to press the Optimize button to create routes and schedules for the entire fleet:

After that’s done, you can fine tune each task, route, or schedule.

That’s the moment when you can rearrange stops to meet order priority.

Or attach documents to meet compliance requirements.

Logistics planners will spend at least 50% less time planning your operations.

(Regardless of the size and complexity of your construction company)

And that means they’ll have more time to spend on other vital areas of your business.

At least, that's how you can do it with eLogii.

Continuous optimization is what every company strives for to stay competitive.

If you’re not improving how you operate, somebody else is.

This can throw you out of the competition.

That is why it is very important to keep doing the fine-tuning.

How is it possible to perpetuate optimization?

Necessity is the mother of invention.

And the more we want to improve our business the more optimizing we have to make.

To find the balance is not easy but it is what separates the leaders from the pack.

A huge part of managing logistics is how you communicate with teams.

Internal communication has to be effective.

Yet kept to a minimum so that it doesn’t draw focus away from critical tasks.

That means reducing chatter while providing accurate information on demand.

SaaS delivery management software helps you achieve all of this.

Because the system is integrated with a mobile app, team members have access to information at all times whenever they are.

They don’t have to call dispatch to find out where the next order is, or what equipment they need to drop off at site A (as opposed to site B).

Instead, they can reserve those calls in case of an emergency.

And if something does happen, they can contact dispatch via the app.

Dispatch also won’t have to talk to field agents all that often.

Logistics managers can see the location of each team member on the map and check their progress via the platform.

They won’t have to keep tabs on people in the field.

And fewer interactions mean fewer distractions and less room for errors.

This system integrates with every part of your organization:

This means you have complete control over resources from a centralized location.

You can choose where to allocate resources. And how much to distribute to aspects of your organization.

This is what gives you flexibility.

It’s also what helps you to build an agile delivery operation.

And with greater flexibility and agility, you raise performance speed and output.

So even with a limited capacity, you still raise how many tasks you handle on a day-to-day basis.

The biggest benefit of using delivery management software is consistency.

Customers love consistency.

They know they can rely on you to do the job. And to do the job exceptionally well

And the better services you provide, the better the customer experience.

Your reputation will grow.

Customers will want to return to do repeat business with you.

They won’t buy construction materials from you once. Or hire on one project.

The customer’s lifetime value will increase.

Your reputation will grow.

As efficiency goes up, you’ll cut costs and slash prices.

That means you’ll be able to provide a better service than competitors at a lower price.

You’ll attract new audiences.

And you’ll use delivery management software to win over customers.

Your reputation will grow.

And so will your revenue.

We can help you with that.

Learn how to reduce costs of your wholesale construction materials delivery by using route optimization software to increase efficiency.

Check out the benefits of optimizing construction materials delivery using software, like eLogii. From fuel and time savings to a boost in sales, and...

Here are nine proven strategies that you can use for continuous building materials supply on projects, construction sites, and contracts.

Be the first to know when new articles are released. eLogii has a market-leading blog and resources centre designed specifically to help business across countless distribution and field-services sub sectors worldwide to succeed with actionable content and tips.