9 Tips for a Continuous Building Materials Supply

Here are nine proven strategies that you can use for continuous building materials supply on projects, construction sites, and contracts.

Home > Blog > 8 Ways to Reduce Delivery Costs in 2024

Delivery LogisticsHere are eight ways that your business can reduce costs in the coming years by taking full advantage of big increases in productivity and efficiency.

With the widespread adoption of eCommerce, delivery costs have become a significant factor in the overall cost of goods.

Delivery costs are also a major reason some businesses succeed while others fail. The high cost of fuel, driver salaries, vehicle maintenance, and delivering items can make the cost of doing business too high for many fledgling businesses.

In this article, we’ll look at how businesses can reduce these costs and make their supply chains more efficient – offering a better experience for customers and employees.

Want to skip ahead? Here’s a summary of our findings:

In a world of constantly rising prices, it seems that the cost of shipping is always going up.

The shipping industry is a key indicator of the health of the economy as a whole, and there are some distinct trends that show why reducing delivery costs is more important now than ever before.

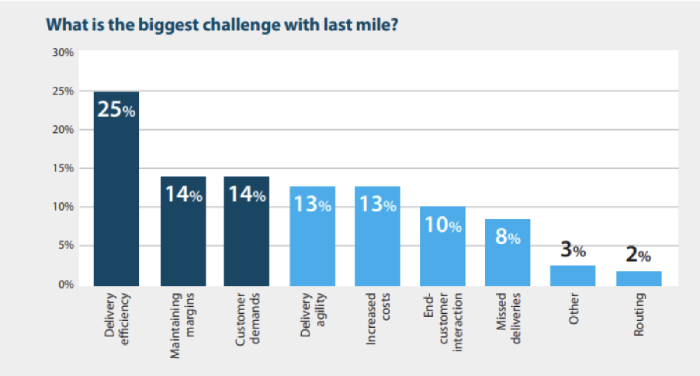

Firstly, 25% of companies named “delivery efficiency” as their biggest last-mile challenge.

Localz - Biggest last mile challenge

Another study pointed out that – unless you optimize last-mile delivery – profits could potentially decline by 26% in three years because of an increase in online sales.

Finally, if you want to stay competitive in the market, you need to consider how you can make your product or service available to customers around the world. This means that you’ll need to find a way to reduce your shipping costs and still offer fast shipping times across multiple countries.

1. Use route optimization software

2. Optimize the packing process

3. Switch to lightweight packing material or corrugated boxes

4. Assign deliveries based on driver and vehicle specifications

5. Use dynamic route optimization over static route optimization

6. Re-negotiate rates with your suppliers

7. Extend your delivery windows for more flexibility

8. Use telematics to find vehicle cost-saving strategies

Route optimization software is a tool that can help you to reduce delivery costs, improve the efficiency of your delivery fleet, and increase customer satisfaction. It’s no wonder that there’s a growing demand for route optimization software (like eLogii).

In fact, the route optimization software market is expected to hit $5.07 billion by 2023.

Take eLogii, for example.

This route optimization tool lets you automatically route, schedule, and dispatch. It’s also accurate, guarantees delivery, and reduces cost, time, and working days.

And that’s not it. It’s inundated with multiple additional features.

eLogii’s key features:

Pros:

Cons:

Use cases:

You can see the value of eLogii by looking at how it worked for National Health Service (NHS) in the UK.

The National Health Service (NHS) is the publicly funded healthcare system in England and is the second largest single-payer healthcare system in the world with an annual budget approaching £200 billion and employing in excess of 1,200,000 full time employees.

The NHS uses eLogii’s route optimization software to boost visibility across their distribution operations. This resulted in a 90% increase in efficiency.

According to Alan Hulme, the NHS' top Facilities Manager, eLogii “surpassed all our expectations”.

“The original route optimization system we had was error-prone and we struggled to scan barcodes accurately. With eLogii scanning is a breeze and the efficiencies we get are amazing. Running reports used to take a day a month (putting together the data etc.) with eLogii it is a click of a button”

Pricing:

eLogii route offers three plans, including:

eLogii uses a customized pricing structure that depends on a few factors specific to your operations.

The packing process is an important part of the supply chain. If you’re not using the right materials, you could be paying more than necessary for shipping or damaging your products before they reach their destination.

There are many factors that go into packing for shipping, but one of the most important is selecting the right material. For example, if you’re shipping glassware, bubble wrap or styrofoam peanuts won’t do much to protect your valuable items from breaking.

The wrong size box can cause damage as well – if a box is too big or too small for its contents, it puts stress on the product during transit.

The best way to avoid these issues is by optimizing your packing process so that it minimizes costs while maximizing protection and performance. You need the right materials and the right containers at the right time.

The best way to reduce the cost of shipping is by using lightweight materials and boxes.

In fact, one 2022 study found that using lightweight packing materials or corrugated boxes can result in a 40% decrease in overall packaging costs. Using these materials will also result in a 50% reduction in landfill waste and a 62% reduction in greenhouse gas emissions (when compared to stiff packaging).

There are many ways to switch to lighter packaging materials. For example, you can use packing peanuts instead of bubble wrap or a lighter-weight box with less cardboard.

Packing peanuts are made from recycled plastic and can be recycled again after use. They come in a variety of sizes and colors so that you can customize them for your product’s needs. You can even print your company logo onto them.

You can also reduce the weight of your packages by switching to smaller boxes.

Deliveries are a crucial part of any business. You have to get your products to the customer somehow. And though we may think of the cost of deliveries as set in stone, this simply isn’t true.

You can reduce costs by assigning deliveries based on driver and vehicle specifications.

For example, if you’re running a restaurant with multiple locations and need to get food from one location to another, it’s best to use an employee who has experience driving that route and knows how to avoid traffic jams and road closures.

Or, if you have two drivers who are used to driving a truck and a small electronic car, respectively, you’ll be able to make more deliveries if you leave each driver to their preferred vehicle.

The same concept applies to companies that deliver goods by truck. These companies may have trucks with different capacities or those that can’t carry certain items, so loads should be assigned according to the characteristics of each vehicle.

Dynamic route optimization is a software-based solution that uses real-time information from the transportation industry to deliver goods to customers in the most efficient way possible.

This technology enables shippers to optimize their supply chain and reduce costs by taking advantage of price fluctuations, traffic conditions, and other factors that impact the cost of shipping goods. Dynamic route optimization also helps companies avoid having to pay high fees for truck capacity when demand is low.

The most common type of dynamic route optimization is called real-time routing. It’s used by many transportation companies to determine the best delivery routes based on real-time conditions.

For example, if there are multiple ways that you could get from point A to point B, real-time routing will calculate which path would be most cost-effective for your business based on factors such as traffic congestion and weather conditions.

You may be able to reduce your delivery costs by re-negotiating rates with your suppliers.

The easiest way to do this is by asking them for better rates. If you have a long-term relationship with them, they may be willing to give you a discount on shipping costs or bulk orders.

You could also look into using a courier or freight company that offers cheaper rates than your current supplier. This will mean finding an alternative supplier, and it might take time to get all of your orders moved over to the new supplier. However, if you find one that can offer much cheaper rates, it might be worth doing so.

Another effective way to re-negotiate rates with your suppliers is to bring new value to your suppliers.

For example, a beverage company that had been facing yearly price increases from a beverage-packaging supplier offered the supplier a market opportunity it couldn’t refuse in return for price concessions. In return for a 10% reduction in price worldwide, the company used the supplier’s cans in the new markets (a win-win situation).

While it’s impossible to eliminate all delivery costs, you can sometimes reduce them by extending your delivery windows (i.e., the time between when the customer places an order and when they receive it).

This will give more flexibility to your suppliers and allow them to deliver when it’s most convenient for them instead of when it’s most convenient for you. This can help reduce the number of trucks on the road at any given time, decreasing the cost of obtaining products.

Extending your delivery windows can be especially beneficial if you’re shipping internationally.

However, the drawback is that your customers might not like the long wait time (though it can still be worth trying if you’re looking to reduce shipping costs at all costs).

The first step in reducing delivery costs is to install a telematics system on your fleet. The second step is to set up a reporting system that allows you to identify areas where you can save money.

Telematics systems allow you to keep track of your fleet’s fuel consumption and driving patterns. This will help you determine if your drivers are accelerating too quickly or braking too hard – things that can result in more gas consumption.

The next step is using this information to create policies that encourage efficient driving habits. You could also consider offering incentives for drivers who drive more efficiently or penalizing those who don’t follow these guidelines.

Telematics systems can also help you identify vehicles that need maintenance before it becomes a problem for your business.

For example, if one of your vehicles needs repairs, it’s better if you know about it before it becomes an emergency situation that could require expensive repairs and downtime during peak periods.

You can see the value of telematics by looking at this case study from Zoetis. Zoetis saved more than 15% in fuel with the telematics software it implemented in several different countries. The company also saw a decrease in the rate of accidents and traffic violations.

If you’ve ever asked yourself, “how can I reduce the cost of product deliveries?” then the above eight strategies should get you started on the road to cutting your shipping costs.

By taking advantage of new digital technologies and adopting a forward-thinking business philosophy, you can slash your delivery costs and offer customers lower prices and increased convenience.

Here are nine proven strategies that you can use for continuous building materials supply on projects, construction sites, and contracts.

Check out the benefits of optimizing construction materials delivery using software, like eLogii. From fuel and time savings to a boost in sales, and...

Explore how you can use delivery management software in construction: for delivering construction materials and managing the logistics on projects.

Be the first to know when new articles are released. eLogii has a market-leading blog and resources centre designed specifically to help business across countless distribution and field-services sub sectors worldwide to succeed with actionable content and tips.