How to Plan and Optimize a Pest Control Schedule

Efficient pest control scheduling boosts satisfaction, saves time, increases profits, and reduces fuel costs with optimized routes and real-time...

Home > Blog > Scaling Your Pest Control Business from 50 to 300 Technicians

Field ServiceA complete guide to scaling up your pest control operations, including appointment planning and scheduling, execution, efficiency and more.

Scaling pest control operations from 50 to 300 technicians isn’t a hiring problem. It’s a systems problem of how you approach growth and operations management.

Up to 50 pest control technicians, your operation still feels manageable. Planners know the routes, recognize the names on the dashboard, and can intervene and fix most issues manually.

At 50, friction starts to surface.

After 50, and up to 300, your field service management system is fighting you.

This guide explains why pest control operations break structurally as you scale.

You’re about to learn precisely how successful pest control companies scaled up, including:

What changes when you grow from 50 to 300 technicians

Why productivity falls as you hire more operations planners

How to design a model that absorbs this complexity instead

And more

If you’re experiencing operational drag, margin pressure, and constant rescheduling chaos, you’re not alone. You’re in this transition, and there’s a solution to scaling your business.

Here’s what you’ll find in this guide at a glance:

Scaling field service pest control increases coordination complexity faster than the number of new employees. What works at 50 technicians (and before), doesn’t scale as you grow to 300.

Adding planners often reduces system clarity as more hands introduce more volatility into the system. Coordination overhead expands faster than operational control improves.

Technician productivity in pest control declines at scale when the number of routes increases and same-day changes compound. Small inefficiencies multiply across the network.

Field service scheduling software works well for planning jobs but struggles under execution uncertainty at scale. The design handles commitments, not continuous re-optimization.

Scaling pest control operations requires you to change the system so it can absorb complexity as your business grows.

Up to 50 technicians, your operation is route-centric:

Each tech works within a zone.

Planners manage daily adjustments.

PPM work sits predictably across the calendar.

Reactive jobs get inserted with manageable disruption.

And any issues that you may encounter are pretty manageable:

Drive time remains stable

Local knowledge compensates for inefficiencies

Informal communication between planners and technicians fills gaps

At 50 technicians (and beyond), pest control operational complexity changes shape.

You now operate across multiple depots or home-based start points for a lot more technicians.

You’re running a mix of residential pest control, commercial contracts, municipal tenders, and ongoing inspections.

You’re juggling pest control PPM and reactive scheduling, including emergency pest control jobs.

As geography expands, SLA pressure increases, and same-day service expectations rise, you begin dealing with:

Multi-region pest control scheduling

Technician specialization

Fumigation and pest spraying with compliance constraints

Emergency pest control capacity buffers

Increased pest inspection scheduling volume

The coordination web thickens.

As you move closer to 300 technicians, you are managing pest control operations at scale. The system is no longer a collection of routes with multiple stops, it’s an interconnected network.

Every decision has second-order impact.

Move one technician and you disrupt five routes. Insert one urgent pest extermination and you create cascading delays. Shift one depot boundary and drive-time inflation ripples across the region.

The transition from 50 to 300 technicians introduces non-linear complexity.

This is a core challenge of pest control growth.

It’s not that your team lost discipline, or that you hired the wrong people. It’s that the operating model built for 50 doesn’t scale cleanly to 300.

And unless you redesign the system, scaling pest control operations will continue to feel harder the bigger you get.

The natural reaction to growth friction is hiring more people.

More technicians. More planners. More dispatch support. It feels logical.

Yet coordination overhead expands faster than headcount.

Every additional technician adds new variables into the mix: start location, skill set, availability, service duration, territory familiarity, customer preferences, compliance constraints.

Every additional planner adds a decision-maker touching the dashboard.

Planner headcount in pest control operations often increases from two to six or eight as companies cross 150 technicians. But instead of improving clarity, the operation fragments.

Planners now:

Reassign jobs manually

Rebuild routes daily

Adjust emergency pest control insertions

Negotiate technician availability

Balance SLAs across regions

The system becomes reactive, while technician productivity declines subtly at first.

Drive times creep up. Duplicate visits increase. Overtime becomes normalized. Gaps appear in the day. Some techs run hot while others idle.

Hiring more technicians doesn’t fix this. It increases workload and pressure on coordination.

When PE backed pest control growth accelerates expansion, the pressure intensifies. Private equity expects clean scaling, predictable margins, and operational leverage.

Instead, complexity compounds.

More people don’t simplify systems. They amplify the existing structure.

If your model relies on human intervention to keep order, growth multiplies fragility. While scaling pest control operations requires structural leverage.

Strong planners are invaluable:

They understand territories

They know technician strengths

They anticipate seasonal surges

They manage emergency work under pressure

But manual coordination doesn’t scale linearly.

As job volume increases, planners spend more time firefighting schedule changes than optimizing operations.

Same-day change drives exponential complexity.

A single late job triggers a shift. That shift delays the next appointment. A reactive call gets inserted. The planner manually adjusts three routes. Another planner adjusts two more. The ripple continues.

Job-centric scheduling struggles under volatility.

Each job is treated independently, so the system doesn’t continuously rebalance the whole workload.

In a 50-tech operation, that works. In a 300-tech network, it fails.

You are now managing:

Route optimization across wide geographies

Specialist resources for fumigation and extermination

Ongoing municipal inspections with strict windows

Reactive jobs with two-hour SLAs

Commercial contracts bundled into facilities management agreements

Cross-service overlaps with waste management or hygiene services

Manual routing becomes a daily reconstruction exercise where planners work harder, the board looks busier, but output doesn't scale. That's because this is a structural issue.

Human-driven planning was designed for low to moderate complexity. At scale, it becomes the bottleneck.

Scaling field service pest control requires a system that continuously recalculates optimal positioning, absorbs volatility, and protects technician performance without manual micromanagement.

Without that, planners remain trapped in reactive coordination.

Most growing operators implement field service scheduling software early in their journey. FSM tools help you to centralize booking, manage work orders, support billing, and improve visibility.

For companies in pest control operations, platforms like FieldRoutes play a critical role in enabling growth from startup to structured business.

But as you move from 50 to 300 technicians, you begin to encounter design boundaries. That’s because FSM platforms are built primarily around job lifecycle management.

They excel at:

Booking software workflows

Customer records

Work order tracking

Billing integration

Basic pest control scheduling software functions

They plan. They dispatch. However, scaling pest control operations at high volatility requires continuous optimization across the entire network.

This is where structural tension appears.

Job-centric scheduling assumes stability. It places appointments on routes based on availability. It allows manual adjustment. It provides visibility.

What it doesn’t inherently do is continuously re-optimize across hundreds of technicians in response to same-day change.

As volume increases, planners rely on:

Dispatch software views

Drag-and-drop route edits

Territory-based logic

Static service windows

The system handles planning, but execution volatility overwhelms it.

FieldRoutes scaling limitations emerge not because the platform is misused, but because its core design focuses on managing jobs, not dynamically optimizing complex field networks.

The same pattern appears in broader FSM platforms such as ServiceTitan, where routing capabilities support dispatch but aren’t built as a dedicated execution-layer optimizer.

At scale, companies encounter:

Route inflation

Manual territory patching

Emergency pest control jobs disrupting entire days

Route optimization handled manually

Increasing planner workload

Inability to reduce drive time

The difference between field routes vs route optimization becomes material.

Route planning assigns work. Optimization rebalances the network continuously.

When scaling field service pest control beyond 50 technicians, the gap becomes visible.

FSM systems aren’t broken. They are operating within their intended scope. But pest control operations at scale require an additional structural capability.

The financial impact of poor structural scaling rarely appears immediately. It accumulates.

Drive-time inflation spreads gradually. Five extra minutes per stop compounds across hundreds of technicians. Over weeks, it erodes technician productivity pest control metrics.

Duplicate visits occur when routing lacks full-network visibility. Reactive jobs trigger inefficient backtracking.

Overtime creeps in. It starts as a seasonal adjustment. It becomes normalized.

SLA risk increases. Emergency pest control commitments create cascading delays. Commercial clients escalate when windows slip.

Margin compression follows.

PE backed pest control growth amplifies scrutiny. Investors examine pest control service cost trends, gross margin stability, and labor efficiency.

If technician output per day declines slightly while headcount grows aggressively, operating leverage disappears.

You may not see dramatic failures.

Instead, you see:

Higher pest control cost per job

Lower jobs per technician per day

Increased planner headcount pest control

Greater coordination time

More internal friction

Without field operations optimization, complexity silently taxes the system.

Scaling pest control operations without optimization is expensive. The cost isn't visible on a single dashboard. It manifests across drive time, overtime, customer churn risk, and managerial attention.

At 300 technicians, small inefficiencies become material.

High-performing operators approaching 300 technicians shift mindset.

They stop thinking in terms of routes.

They think in terms of networks. They define planning, scheduling, execution, and optimization as distinct layers:

Planning defines capacity and coverage.

Scheduling places commitments on the calendar.

Execution delivers jobs in real time.

Optimization continuously recalibrates positioning.

They treat pest control route planning as a dynamic problem, not a static assignment. They account for:

Multi-depot configurations

Home-based technicians

Regional density variations

Emergency pest control capacity buffers

Municipal contracts with strict SLAs

Mixed residential and commercial flows

They move beyond job-centric logic.

They implement systems capable of real-time pest extermination route optimization. Systems that rebalance work automatically as volatility enters the day.

They protect technician productivity pest control metrics deliberately.

They measure drive time as a controllable variable.

They use field service scheduling software for planning and billing, while adding execution-layer intelligence to maintain control under complexity.

They accept that pest control growth challenges are structural. They design systems that scale with volume rather than relying on planner heroics.

That is the difference.

Most pest control operations conflate planning with execution.

Planning happens in advance → Execution happens in motion.

At 50 technicians, the gap between them is manageable. At 300, it becomes the central problem.

Planning systems assign work based on expected conditions.

Execution reality diverges immediately.

Traffic. Cancellations. Overruns. Emergency pest control insertions. Technician availability changes. Weather impact on fumigation schedules.

Without an execution layer, planners manually reconcile variance. That reconciliation becomes constant.

Execution-layer systems operate differently.

They monitor technician location, job progress, SLA commitments, and capacity buffers continuously. They optimize globally, not locally.

Instead of asking planners to reshuffle jobs, the system recalculates positioning across the network. This is field operations optimization applied to pest control operations:

It reduces drive time pest control exposure.

It protects SLA adherence.

It stabilizes technician productivity pest control.

Scaling field service pest control requires this capability because complexity no longer sits at the planning stage. It lives in execution.

When you cross 50 technicians, you are no longer managing individual routes. You are managing an adaptive network.

Scaling requires systems that absorb complexity, not people who fight it.

Pest control businesses that are expanding operations from 50 to 300 technicians increasingly introduce an execution layer alongside their existing FSM platform.

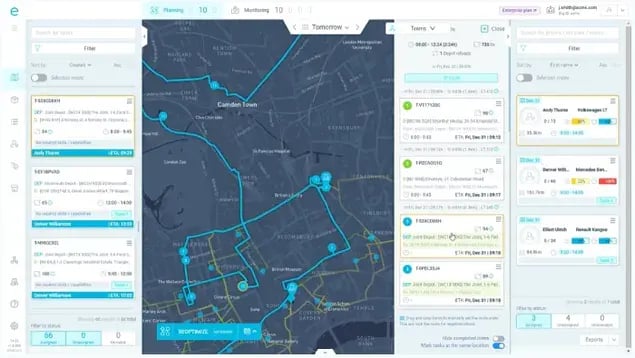

This execution layer is where eLogii fits in.

Companies like Vergo Pest Management from the UK are using eLogii to grow their operations without compromising efficiency at scale:

Most importantly for pest control businesses, eLogii doesn’t replace existing systems like FieldRoutes, ServiceTitan, and other ERP, CRM, CAFM, and FSM tools. It plugs into them.

Field service scheduling software continues to manage customer records, booking workflows, pest control booking software logic, pest inspection scheduling, and billing.

eLogii operates as the execution layer that allows you to continuously optimize routing across technicians, depots, and regions.

Our software adapts to emergency pest control jobs, mixed PPM and reactive scheduling, expanding geography, and increasing SLA pressure without requiring planners to manually rebuild routes.

As companies scale pest control operations, same-day volatility isn’t the exception anymore. Cancellations, overruns, technician absence, traffic conditions, and high-priority commercial requests constantly reshape the day.

So instead of reacting to each disruption manually, eLogii recalculates positioning across the network. In doing so, it balances capacity, protects service windows, and stabilizes technician productivity metrics across service zones.

This is particularly valuable if you’re looking to expand into multi-region pest control scheduling with home-based technicians and multiple depots.

Instead of increasing planner headcount endlessly, you can shift coordination workloads into the system, and move planners from firefighting mode into oversight of your operational network.

The result is structural control over operational complexity.

Not through more people. But through architecture designed specifically for scaling pest control operations.

This model fits companies experiencing:

50+ technicians and growing fast

Multi-region pest control scheduling complexity

Mixed residential and commercial portfolios

PE backed pest control growth pressure

Increasing SLA commitments

It's less relevant for small, single-territory operators with stable routing and low volatility.

|

Traditional Planning |

Execution-Layer Model |

|

|

< 50 technicians, single region |

Works well |

Not critical |

|

> 50 technicians, growing regionally |

Increasing friction |

Strong leverage |

|

300 technicians, multi-region operations |

High planner load, margin pressure |

Structural stability |

|

PE-backed rapid expansion |

Fragile coordination |

Scalable architecture |

If scaling pest control operations feels harder each quarter despite hiring, you are likely in this transition zone.

Scaling from 50 to 300 technicians changes the nature of pest control operations.

You move from managing routes to managing a system.

Hiring more planners doesn't resolve pest control operational complexity. It often amplifies it.

Planner heroics can't compensate for structural gaps indefinitely. FSM platforms provide critical planning infrastructure, but execution volatility requires additional capability.

The companies that scale cleanly separate planning from optimization. They design networks that absorb change.

If you’re navigating pest control growth challenges and feeling margin compression, coordination drag, or declining technician productivity pest control metrics, the issue is not effort.

It’s structure.

See how scaled pest operations maintain control.

Efficient pest control scheduling boosts satisfaction, saves time, increases profits, and reduces fuel costs with optimized routes and real-time...

Discover the 10 best routing apps for pest control businesses in 2024. Compare features, pricing, and use cases to find the perfect fit for your...

Start and optimize your pest control and landscaping business with tips on licensing, combining services, scaling efficiently, and boosting...

Be the first to know when new articles are released. eLogii has a market-leading blog and resources centre designed specifically to help business across countless distribution and field-services sub sectors worldwide to succeed with actionable content and tips.