Reorder Point: How to Calculate It + How to Cut Costs

Calculate reorder points to optimize inventory and save costs. Align inventory with demand for better sales and reduced expenses.

Home > Blog > Why Pest Control Routing Fall Apart as Your Operations Scale

Field ServiceFind out why pest control routing collapses at scale, and how better managing execution, not better planning, impacts success of multi-region operations.

When pest control routing breaks down, it’s not a surprise to anyone.

On the planning board, route optimization for pest control looks clean. But once the day starts, the system starts losing control faster than anyone expected. (Not even to your most recent planners.)

The issue isn’t your people, their discipline, or your organization’s collective effort.

So, what is it then?

It’s the structural mismatch between how pest control operations actually behave, and how traditional pest control scheduling and routing systems assume it will behave.

This article examines the precise moment in your operations when this happens. When does pest control routing collapse, and why does this happen predictably as organizations grow past a certain size and complexity.

If you lead pest control operations across regions, depots, or dozens of technicians, this will feel uncomfortably familiar.

But the goal here is clarity:

Understanding why your routing struggles daily, and why “planning better routes” or “planning harder” never seems to fix it.

Here’s what else you can expect to see:

Pest control routing failures emerge from structural instability, not weak planning discipline. Static routing systems assume stability that pest control operations never have.

As pest control operations scale, variability compounds faster than planning complexity can absorb. This is why pest control route planning often collapses by mid-morning.

FSM-native pest control scheduling tools were designed for batch planning, not continuous execution control. Their limitations surface once reactive work accelerates.

Mid-day disruptions create cascading effects across technicians, routes, and SLAs. One late job silently inflates drive time across the entire operation.

High-maturity pest control operations manage execution dynamically. They treat plans as starting points, not fixed commitments.

When pest control routing begins to fall apart, organizations almost always respond in the same way:

You plan harder

You plan longer

You add structure

You tighten rules

You increase oversight

More time is spent building routes. Pest control route planning sessions move earlier in the day or later into the evening. Planners refine technician territories. Dispatch rules get stricter. Customer time windows are narrowed. Buffers are added, then reduced, then re-added.

From an operations leadership perspective, this response makes sense.

Route planning is visible. Effort is measurable. Control feels achievable at the planning stage. COOs can see schedules, routes, and utilization metrics. While better-looking pest control routing plans signal operational maturity.

Internally, these efforts are often rewarded. Teams that produce clean, dense pest inspection maps appear disciplined. You see fewer open jobs at dispatch. Forecasted utilization improves. On paper, pest control scheduling looks under control.

All of this is important. But the problem is that all of this assumes the plan is the system. It’s not.

In reality, the plan is only an initial condition:

Pest control routing lives or dies during execution, not planning.

As organizations scale to 50, 100, or 300 technicians across regions, planning complexity grows exponentially.

Multi-region pest control scheduling introduces depot variation, technician start locations, mixed residential and commercial accounts, and varying SLAs.

The response is more planning effort layered onto static assumptions.

This works, for a moment. Then the first disruption hits, and your whole structure fractures.

At 7:00 AM, pest control routes look clean. They’re compact. Drive time is optimized. Each technician has a full day of PPM work, inspections, or recurring pest treatments. Dispatch confidence is high.

By 8:45 AM, the first job runs long. A commercial site requires additional treatment services. A residential customer asks questions. Documentation takes longer than planned. The technician is now 20 minutes behind.

At 9:30 AM, an emergency pest removal job arrives. A restaurant reports rodent activity. An SLA demands same-day service. Dispatch inserts the job into the nearest route. Pest control routing shifts slightly.

By 10:30 AM, another reactive call comes in. Then another. A technician hits traffic. A customer isn’t home. A gate code doesn’t work. Each event is small. Each seems manageable.

Your route planners start intervening. They move jobs manually. They call technicians. They reassign work. Pest control scheduling becomes a live-fire exercise.

By noon, routes are fragmented. Drive time has increased. Technicians are skipping breaks. The original pest control route planning bears little resemblance to reality.

“If your pest routes regularly collapse by mid-day, this isn’t a planning failure.”

This is the natural behavior of pest control routing under scale.

Pest control operations have uniquely low tolerance for disruption. Compared to HVAC, utilities, or telecom, pest control routing operates with far tighter margins:

Visit density is high: Technicians may complete 12–20 stops per day. Each job is short, often 15–30 minutes. There is little buffer between appointments. So, a 10-minute overrun matters.

Customer expectations are unforgiving: Residential customers expect punctuality. Commercial clients demand discretion and compliance. Municipal pest control contracts carry strict SLAs. Missed windows escalate quickly.

Reactive work is inherent: Pest infestations do not respect schedules. Emergency pest control jobs override the plan. Pest control PPM and reactive scheduling coexist uneasily in the same day.

Technician start points are fragmented: Many technicians start from home. Others start from depots. Multi-depot operations complicate pest extermination route planning further.

All of this creates a system with minimal idle time. There is no excess capacity waiting to absorb disruption. Every minute matters.

“Pest control has less slack in the system than most field services.”

This fragility is why pest control routing fails sooner as organizations scale. The operating model itself amplifies variability.

Planned preventative maintenance (PPM) fills most pest control schedules. PPM work creates predictable revenue and recurring routes. Pest control routing is often optimized around these visits.

But reactive work is unavoidable. Emergency pest control jobs arrive unpredictably. SLAs require rapid response. These jobs cannot wait for tomorrow’s plan.

When a reactive job enters the system, it displaces something else. A PPM visit is delayed, moved, or rushed. That change cascades. The technician’s next jobs shift. Customer windows tighten.

FSM-native pest control scheduling tools typically replan in batches. They are excellent at building tomorrow’s routes. They struggle to adapt continuously throughout the day.

Each reactive insertion forces a local optimization that harms the global plan. Drive time increases. Routes fragment. Technicians cross territories.

This isn’t poor dispatching. It’s structural.

Pest control routing systems are being asked to do something they were not designed to do: continuously rebalance execution under constant change.

As scale increases, the frequency of reactive work rises. Multi-region pest control operations see more variability simply because volume is higher.

The mid-day collapse becomes inevitable.

FieldRoutes and ServiceTitan are powerful platforms for pest control operations management.

These platforms allow you to handle billing, CRM, compliance, and long-term scheduling extremely well. Many operators run their businesses on them successfully.

However:

These are FSM-native scheduling software for pest control. They assume relative stability during execution. Routes are planned in advance. Changes are expected to be exceptions, not the norm.

FieldRoutes scheduling limitations appear once pest control routing requires continuous adjustment. The system is optimized for batch planning, not real-time re-optimization.

ServiceTitan pest control routing faces similar boundaries. When jobs change mid-day, planners intervene manually. The software records the change, but it does not actively manage the cascading effects.

This isn’t a configuration issue. It’s not a training problem. It’s a design boundary.

FSM platforms were built to manage work orders and schedules, not to dynamically control execution minute-by-minute, job-to-job.

As pest control operations scale, these limitations become visible. Planners spend their days firefighting. Dispatch becomes reactive. The system loses control by mid-day.

Understanding this distinction is critical:

Pest control routing failure isn’t a verdict on FieldRoutes or ServiceTitan. It’s acknowledgment that execution complexity has outgrown your static scheduling assumptions.

Consider a single job running 20 minutes late:

That technician now arrives late to the next appointment. The customer is annoyed. The technician rushes.

The third job slips:

Dispatch inserts an emergency pest control call nearby. The technician detours. Drive time increases.

Another technician is asked to cover a skipped job:

Their route stretches. They cross territories. Their afternoon appointments compress.

By mid-afternoon, multiple technicians are behind. Planners are manually reshuffling work. Pest control routing has fragmented into disconnected decisions.

Each small change compounds. Drive time inflation reduces capacity. Missed windows trigger SLA pressure. Customer satisfaction erodes quietly.

This is the domino effect of static pest control route planning in a dynamic environment.

No single failure causes it.

The system simply cannot absorb continuous variability.

The most damaging costs of pest control routing failure aren’t dramatic. They are cumulative.

Capacity erosion: A technician completes one fewer job per day. Not because they worked slower, but because drive time expanded and buffers vanished. One job lost per technician per day across 80 technicians is not a rounding error—it is a structural capacity leak.

Overtime: Technicians stay late to finish routes that looked reasonable at 7 a.m. Labor costs rise incrementally. No single day looks alarming, but monthly payroll trends drift upward.

Planner productivity: Instead of improving pest inspection route optimization or refining territories, planners spend their days firefighting. Their role shifts from strategic control to tactical survival. Burnout follows.

SLA risk: Most commitments are technically met—but barely. There is no margin. One more emergency job, one more delay, and escalation becomes unavoidable.

Customer dissatisfaction: Appointments slide. Communication becomes reactive. Commercial clients notice inconsistency. Residential customers feel deprioritized. Churn risk increases without a clear trigger event.

These are slow leaks, not explosions.

Pest control operations feel permanently busy, always stretched, never stable.

That’s why scaling pest control operations under these conditions feels harder every quarter. Even when demand for your services is strong.

When these symptoms appear, leadership often doubles down on planning:

Routes are tightened

Buffers are debated

Standards are reinforced

This usually makes things worse.

Over-planning increases brittleness: The tighter the pest control route planning, the less capacity it has to flex when reality intervenes. Dense routes look efficient, but they are fragile.

Static plans cannot absorb guaranteed variability: Pest control work is inherently unpredictable. Job durations vary. Reactive work is unavoidable. Traffic, access issues, and customer behavior cannot be normalized away.

Manual intervention doesn’t scale: A skilled planner can manage disruption across 15–20 technicians. At 50 technicians, they are stretched. At 100 technicians, the model breaks entirely. The system becomes dependent on heroic effort.

This is our core insight:

“You can’t plan away variability that is structurally guaranteed.”

Pest control routing doesn’t fail because planning is weak, but because planning is used to solve an execution problem.

No amount of discipline can overcome that mismatch.

High-maturity pest control operations behave differently.

Large-scale pest management operations don’t plan more because they execute differently.

They treat daily plans, routes, and schedules as starting points, not a contract. The plan sets intent, not rigid commitments. Change is expected.

They continuously re-optimize throughout the day.

When a job runs long or a reactive call arrives, the system recalculates impact across routes, not just locally. Decisions consider the whole network, not just the nearest technician.

Rules and constraints guide decisions.

Technician skills, SLAs, customer priorities, and drive-time thresholds are enforced consistently. Manual judgment is reserved for true exceptions.

Planners supervise outcomes instead of moving jobs.

They monitor KPIs, exception queues, and risk signals. Intervention becomes strategic rather than constant.

Execution control replaces static scheduling.

Pest control routing becomes adaptive, resilient, and visible throughout the day. Not just for dispatch.

This is how control is restored at scale.

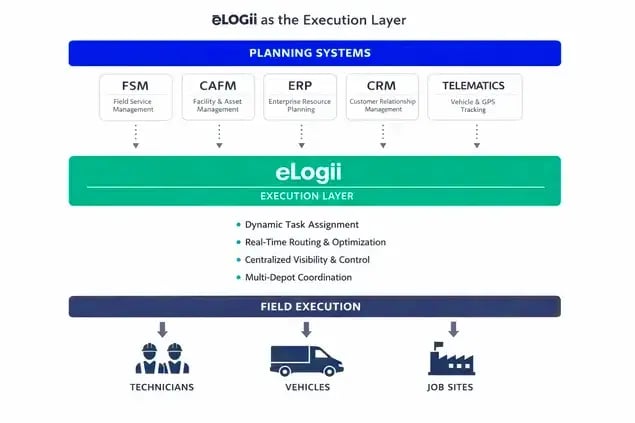

eLogii operates at the execution layer—between planning and the field—where the real complexity of pest control routing emerges.

While traditional FSM-native systems like FieldRoutes and ServiceTitan excel at creating structured schedules, they are built around the assumption of relative stability.

If you subscribe to these systems, you should still use them to handle batch planning, route generation, and technician assignment effectively. But you need to keep in mind that they’re not designed to continuously absorb mid-day variability.

This is where eLogii provides an extra layer to pest control management:

eLogii doesn’t replace the plan. Instead, the software continuously monitors, rebalances, and adapts routes in real time as conditions change.

Our system assumes variability as a given rather than an exception.

Emergency pest control calls, traffic delays, no-shows, extended treatment times, and multi-depot start points are all expected inputs, not anomalies.

When a technician is delayed or a reactive call comes in, eLogii recalculates the most efficient adjustments across multiple routes simultaneously.

This reduces drive-time inflation, preserves SLA compliance, and minimizes fragmented routing. All without requiring planners to manually intervene on every exception.

Integration is seamless and additive with eLogii.

The software works alongside FieldRoutes, ServiceTitan, or similar systems, leveraging their core strengths in scheduling, CRM, and billing while handling the dynamic execution challenges that scale introduces.

Multi-region pest control operations, teams with 50+ technicians, and organizations balancing PPM and reactive work all benefit from this separation of responsibilities:

Planning remains the domain of existing FSM systems, and execution control is handled dynamically.

The value is subtle but crucial:

It isn’t about building a “better plan” the night before. It’s about maintaining operational control in the field as reality unfolds.

For teams experiencing predictable mid-day collapse, eLogii ensures the plan remains a useful guide rather than a fragile illusion.

This perspective is for pest control leaders managing real operational complexity.

It’s designed for multi-region operations with multiple depots and home-based technicians.

For organizations running 50+ technicians.

For teams balancing pest control PPM and reactive scheduling across residential, commercial, and municipal customers.

It isn’t for small, stable, local pest control teams with low variability. If routes rarely change mid-day and reactive work is minimal, static planning may be sufficient.

|

This Is For You |

This Isn’t For You |

|

|

Scale |

Designed for operations with 50+ technicians across multiple regions or depots, where execution complexity grows exponentially |

Suited for small, local teams where routes rarely change, and a single planner can manage the full operation. |

|

Variability |

Handles high variability in job durations, traffic, emergency calls, and customer availability. The system expects mid-day changes as normal. |

Assumes predictable, low-variability workflows with minimal reactive work. Disruptions are treated as exceptions not structural features. |

|

Planning |

Planning is adaptive; routes are starting points, continuously updated based on live conditions. Planners focus on strategy and supervision not firefighting. |

Planning is static; routes are fixed in advance. Planners intervene manually when things go wrong, often creating more fragility. |

|

Execution |

Execution is dynamic; the system actively monitors field activity, adjusting assignments and priorities in real time. |

Execution is reactive; success depends on technicians and planners responding manually. |

|

Routing |

Routes are continuously optimized during the day, factoring in delays, emergency calls, and technician location. |

Routes are built once, typically the night before or early morning, with minimal real-time adjustment. |

|

Dispatch |

Dispatch is rules-based, automatically integrating SLAs, technician skills, and current location to make decisions under changing conditions. |

Dispatch relies on manual judgment and ad-hoc decisions, often creating inefficiencies and coverage gaps. |

|

SLAs |

SLAs are actively managed during the day; the system prioritizes urgent calls and monitors compliance continuously. |

SLA compliance is reviewed end-of-day, often revealing missed commitments after the fact. |

|

Visibility |

Provides live, real-time execution state for every technician and route, allowing rapid intervention before delays cascade. |

Visibility is retrospective; reports show what happened, not what is happening, limiting proactive control. |

|

Control |

Control occurs during execution; planners influence outcomes without micromanaging every job, preserving system resilience. |

Control is assumed to occur during planning; execution relies heavily on manual adjustments to maintain service levels. |

|

Growth |

Supports growth; operational complexity can increase without adding more planners or sacrificing service quality. |

Growth is constrained; adding technicians or regions rapidly overwhelms existing staff. |

Pest control routing doesn’t fall apart because your teams lack discipline, skill, or effort.

Route optimization fails because execution complexity overwhelms systems created for stability.

Once you recognize this, the conversation changes. And mindset shifts.

The question is no longer:

How to plan better routes?

But:

How to maintain control and efficient routes as the day unfolds?

And if you’re asking yourself the same question, we can help you.

Calculate reorder points to optimize inventory and save costs. Align inventory with demand for better sales and reduced expenses.

From better driver management through fuel and cost reduction, to more profit, this article shows you 16 benefits of driver route software.

Find out why better field service planning doesn't improve your operations, and what you should do instead to restore control, resilience, and...

Be the first to know when new articles are released. eLogii has a market-leading blog and resources centre designed specifically to help business across countless distribution and field-services sub sectors worldwide to succeed with actionable content and tips.