Sales Route Planner: How to Boost Profitability + Efficiency

Boost sales efficiency and profits with our route planner. Optimize routes, prioritize leads, and streamline field sales operations for maximum...

Home > Blog > Field Service Planner Trap: Why Hiring More Planners Doesn’t Fix Missed SLAs

Field ServiceHiring planners faster than the operation grows? SLAs still get missed? You may have fallen into the field service planner trap. Here's how to fix it.

Your field service planner team keeps growing, but performance doesn’t. Missed SLA targets remain red, even after you hire more operations planners year after year.

This guide explains why that pattern is so common in large, 50+ field technician, SLA-driven operations, and why it doesn’t work.

We’ll explain how planners slowly turn into the execution engine, why complexity multiplies faster than headcount, and why adding more people brings short-term relief but not long-term stability.

It breaks down what actually causes SLA performance to stall, where scheduling tools fall short, and what you can change when execution decisions move out of human hands.

If you’ve scaled planning teams without focusing on outcomes, this will feel uncomfortably familiar. But the solution will also finally make sense.

Here’s what you’ll get from this guide:

SLA performance often declines even as planner headcount rises because new planners manage complexity, not reduce it.

Each new operational variable multiplies planning decisions, driving reactive scheduling and planner overload.

FSM tools and improved processes help organize work but don't absorb execution complexity.

Adding planners increases coordination overhead, introduces delays, and risks inconsistent decision-making.

True SLA improvement requires an execution layer that automates trade-offs, reprioritizes in real time, and reduces reliance on human planners.

In large, multi-region field service operations, planners are more than schedulers. Their day-to-day work is dominated by constant reprioritization and conflict resolution.

Reactive callouts, emergency jobs, and customer escalations interrupt static schedules, force planners to adapt continuously. It's the planner's job to manually protect SLAs by moving appointments, reassigning technicians, and negotiating with customers.

They absorb uncertainty and act as the execution engine for operations, ensuring that SLAs are met despite disruptions.

In practice, a field service planner’s work often looks like:

Dynamic scheduling: adjusting technician itineraries multiple times per day to accommodate urgent jobs.

Conflict resolution: managing overlapping appointments, equipment shortages, and travel constraints.

Reactive workload absorption: responding to same-day change requests, cancellations, or emergency callouts.

SLA monitoring and escalation: prioritizing jobs to prevent SLA breaches and managing exceptions manually.

The key point:

Planners don't just plan, they execute in real time.

In operations with 50+ technicians across multiple regions and depots, planners are the operational firewall between SLA targets and missed SLAs.

They are essential, but they aren't scalable without adding layers of coordination.

Adding planners is the default response to execution failure, but the forces driving headcount growth are structural:

Reactive callouts multiply with scale: the larger the operation, the more urgent jobs appear unexpectedly. Each incident triggers a chain of scheduling adjustments.

Same-day changes dominate schedules: technician availability, site readiness, and customer rescheduling require planners to reconfigure assignments continuously.

Multi-region coordination adds complexity: synchronizing work across depots and territories multiplies decision points and increases planner load.

Customer escalations create exceptions: Important clients or high-priority contracts demand immediate attention, often overriding standard planning rules.

SLA overrides proliferate: planners are frequently asked to bend rules to prevent SLA breaches, further increasing manual intervention.

Each new variable multiplies the number of decisions planners must make. But adding a planner doesn't reduce this complexity, it simply spreads it across more people.

In fact, the more planners you hire, the more coordination is needed between them, which creates a self-reinforcing cycle of growth.

Result: Field service planner headcount grows faster than the operation itself, yet SLA performance within your field operations struggles to stabilize.

Increasing headcount appears logical, but it rarely improves SLA outcomes. There are several reasons:

Coordination overhead increases: every new planner adds communication layers. Decisions must be synchronized, handoffs occur, and alignment meetings multiply.

Handoffs and delays multiply: when one planner makes a decision that affects another planner’s assignments, delays occur. Execution slows rather than accelerates.

Inconsistent decision-making emerges: multiple planners applying subjective judgment leads to varied prioritization and SLA interpretation, risking errors.

Diminishing returns: after a certain point, adding planners reduces stress temporarily but doesn't address the root causes of missed SLAs in field service.

More planners add coordination, not control.

SLA performance isn't a function of the number of humans managing schedules but of how execution complexity is absorbed. When operations rely solely on manual planning, the system can't keep pace with real-time changes.

Even in organizations with FSM tools and structured processes, SLA traps persist because human planners are the bottleneck.

They can't manage the combinatorial growth of decisions that come with larger, multi-region operations.

Adding planners may seem like a logical solution to SLA pressure, but the hidden costs of relying on planner-led execution are substantial, spanning financial, operational, and human dimensions.

Field service planners are highly skilled, and their compensation reflects the complexity of their work. In large enterprises, incremental headcount quickly escalates costs:

Each planner requires salary, benefits, and training. Multi-region operations may require additional allowances, travel support, or localized expertise.

Growing planner teams often trigger new management layers, adding supervisory salaries and administrative overhead.

The cost scales linearly with headcount but doesn't translate into proportional improvements in SLA performance, creating diminishing returns.

Ironically, adding more planners can slow operational responsiveness:

Coordination between multiple planners introduces delays in implementing schedule changes.

Handoffs and approvals multiply, creating bottlenecks when urgent jobs or reactive scheduling requests arrive.

Delayed execution increases the risk of SLA breaches, especially in multi-depot or multi-region operations where timing is critical.

Manual scheduling struggles to optimize travel, skills, and workload simultaneously:

Technicians may be assigned sequential jobs that increase travel time, reducing overall productivity.

Skill mismatches or unavailable equipment often leave technicians idle.

Multi-region operations exacerbate underutilization as planners scramble to balance competing priorities without automated optimization.

Planner-led execution is high-stakes, high-pressure work:

Constant SLA monitoring and reactive scheduling contribute to stress and fatigue.

Burnout leads to higher turnover, resulting in the loss of institutional knowledge and repeated recruitment and training cycles.

New hires take time to reach full effectiveness, further straining SLA performance during transition periods.

Larger planner teams introduce additional layers of oversight:

Coordination meetings, reporting cycles, and cross-team communications multiply.

Policies, escalation rules, and playbooks must be constantly reinforced to maintain consistency.

Each layer of management adds potential delays, reducing agility and slowing SLA response.

Beyond direct costs, there is a strategic opportunity cost:

Planners occupied with firefighting can't focus on optimizing processes, improving SLA reporting, or implementing long-term efficiency initiatives.

Investment in headcount can crowd out investment in execution-layer systems that reduce human dependency and stabilize SLA performance.

CFOs reviewing operational headcount planning quickly recognize that hiring planners is expensive, unsustainable, and only partially effective.

Planner-led execution addresses symptoms, reactive scheduling, conflicts, and SLA overrides, but it doesn't resolve the root cause:

Real-time execution complexity.

Without systems that absorb this complexity, your organization may continue to experience planner overload, missed SLAs, and escalating operational costs, despite ongoing headcount growth.

Field Service Management (FSM) and scheduling tools are often the first solution organizations turn to when SLA performance falters.

Systems like FSM, CAFM, ERP, CRM, telematics, and scheduling software provide structure, visibility, and reporting.

But they can't absorb the complexity of real-time execution that occurs in large-scale field service operations.

FSM systems excel at static scheduling, basic dispatching, and SLA tracking.

You can use them to assign jobs based on technician availability, skills, or geography, and provide dashboards for SLA compliance monitoring.

However:

These software capabilities are fundamentally planning-oriented, not execution-oriented.

While FSM tools give you visibility into schedules and workloads, they can't automatically respond to the disruptions that occur throughout the day. Which leaves your planners intervening constantly.

Most FSM solutions operate under static assumptions:

Technicians complete jobs as scheduled

Travel times are predictable

No urgent requests will appear mid-day

In complex, multi-region operations, these assumptions are rarely valid.

Equipment delays, traffic disruptions, reactive maintenance calls, and customer escalations continuously invalidate static schedules.

Planners must step in manually to reassign technicians and resolve conflicts, keeping SLA performance in field operations at risk.

Despite FSM tools, planners continue to act as the execution engine.

Every urgent job, last-minute cancellation, or SLA override requires human judgement. The system can highlight risks but can't resolve them autonomously.

As a result, planners remain overloaded, reactive, and unable to focus on strategic initiatives.

FSM tools organize work, they don't absorb execution complexity.

Missed SLAs persist because the system can't dynamically optimize schedules in real time.

The larger and more complex the operation, multiple depots, regions, and technicians, the greater the reliance on planners to intervene manually.

Investing in FSM solutions without an execution-layer capability is insufficient to stabilize SLA performance.

Planners remain the bottleneck, coordination demands continue to rise, and missed SLAs remain a chronic operational challenge.

FSM tools provide structure and visibility, but they don't solve the root cause: real-time execution complexity.

Process improvements such as escalation rules, playbooks, or tighter governance provide structure, but they can't substitute for real-time decision-making.

Escalation rules: create clear pathways for exceptions and define who should act when SLAs are at risk, but they don't reduce the sheer number of decisions required during execution spikes. Multiple escalations can overlap, creating conflicts that planners must resolve manually.

Playbooks: standardize responses to common scenarios and provide guidance on prioritization, yet they can't anticipate every exception in complex, multi-region operations. A reactive PPM job in one depot might disrupt schedules in another, requiring judgement calls outside any predefined playbook.

Tighter governance: improves consistency by enforcing approval steps, reporting requirements, and escalation criteria, but it slows reaction to urgent changes. Paradoxically, the more rigid the governance, the higher the risk of SLA breaches when real-time adjustments are needed.

You can't process your way out of real-time complexity.

SLA performance is determined by the ability to make dynamic, continuous execution decisions with full awareness of technician location, skill sets, availability, and travel constraints.

Even the most disciplined processes will fail under the pressure of multi-depot, multi-region operations, where reactive scheduling field service dominates and operational conditions change hourly.

In large, multi-region field service operations, adding headcount alone rarely stabilizes SLA performance.

The real improvements occur when execution complexity is systematically removed from human planners, allowing them to focus on strategic exceptions rather than firefighting.

Several capabilities enable this transformation:

Dynamic conditions, traffic delays, technician absences, equipment unavailability, or same-day reactive jobs, constantly disrupt static schedules. Continuous re-optimization ensures that schedules adapt automatically in real time:

Job sequences are recalculated as new tasks arrive or existing appointments are delayed.

Technician assignments are adjusted based on location, skill sets, and workload balance.

Multi-depot operations are synchronized, ensuring that resources are efficiently allocated across regions without manual intervention.

By absorbing variability automatically, continuous re-optimization reduces the burden on planners to manually reassign work and prevents SLA breaches before they occur.

Not all jobs are equal, urgent, high-priority, or SLA-critical jobs must take precedence. SLA-aware prioritization enables systems to rank work dynamically according to urgency, SLA targets, and operational constraints:

Jobs at risk of breaching SLA thresholds are automatically moved higher in the schedule.

Technician allocation considers not only availability but also the impact of delays on SLA compliance and first-time fix rates.

Reactive scheduling field service, such as same-day callouts or escalations, is handled without planners needing to manually intervene.

This approach ensures SLA performance field operations remain stable even under heavy workload pressure.

Optimizing SLA adherence requires balancing multiple, sometimes competing objectives: technician utilization, travel efficiency, and SLA compliance. Automated trade-offs allow the system to make real-time decisions that optimize across these dimensions:

Technician might be reassigned from a lower-priority jobs to prevent an SLA breach elsewhere.

Routes and service windows are recalculated to maximize first-time fix rates and minimize idle time.

Resource allocation adjusts dynamically as incidents arise, without planners having to resolve conflicts manually.

By embedding planners’ experience and judgement into automated logic, rules-based decisioning reduces ad hoc human intervention:

Standard procedures, such as handling urgent callouts, SLA overrides, or skill mismatches, are codified in system logic.

Exceptions are escalated only when they can't be resolved automatically, freeing planners to focus on strategic issues.

Multi-region, multi-depot complexities are absorbed systematically, preventing inconsistencies and errors in prioritization.

When these capabilities are implemented, the results are measurable and transformative:

SLA breaches decrease because reactive work and prioritization are handled automatically.

Planner stress declines as the daily firefighting load drops.

Technician productivity rises as schedules are optimized dynamically for travel efficiency, skill alignment, and workload balance.

Operational headcount planning becomes more predictable, as fewer additional planners are needed to manage complexity.

In other words:

SLA performance improves when the system takes execution decisions away from human planners and operates as a real-time execution layer.

Planners transition from being reactive schedulers to strategic overseers, ensuring that field operations are both resilient and scalable.

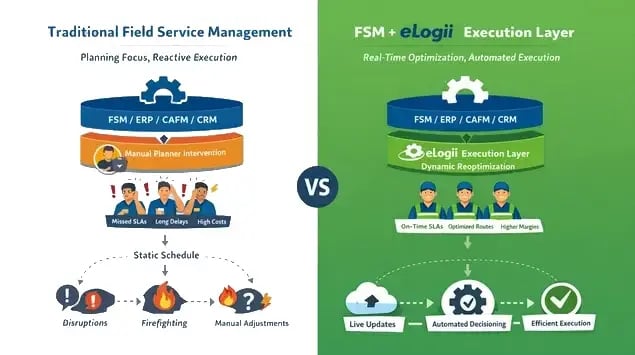

eLogii functions as an execution layer built specifically to absorb the real-time complexity that overwhelms human planners in large-scale field service operations.

Unlike FSM or CAFM systems, which organize work and provide visibility, eLogii actively manages execution decisions. The software continuously re-optimizing schedules, prioritizing SLA-critical jobs, and automating trade-offs between competing objectives.

It complements existing systems (FSM, CAFM, ERP, CRM, Telematics) rather than replacing them, integrating seamlessly into current operational workflows.

By dynamically adjusting schedules across multiple depots, regions, and technician skill sets, eLogii reduces the manual burden on planners while improving SLA performance.

Reactive callouts, last-minute cancellations, and emergency escalations are handled automatically, preventing the constant firefighting that drives planner overload. Planners can focus on strategic oversight, exception management, and continuous improvement rather than micro-managing each schedule change.

Multi-region, multi-depot field service teams gain tangible benefits:

Control: consistent decision-making across regions and depots ensures SLA adherence and uniform service standards.

Visibility: real-time insights into technician locations, job progress, and SLA compliance support proactive management rather than reactive crisis handling.

Efficiency: reduced planner load and optimized technician allocation increase utilization and reduce idle time.

Re-optimization: continuous adjustments balance SLA compliance, travel efficiency, and first-time fix rates, ensuring resources are deployed where they deliver maximum impact.

Essentially:

eLogii closes the gap between your static planning and dynamic execution.

It transforms SLA management from a reactive, planner-intensive process into a predictable, optimized, and scalable operation.

This is what allows your organization to stabilize SLA performance without continually increasing field service planner headcount.

This table helps you quickly assess whether this article applies to your operation and contrasts operational realities side by side.

If you recognize your environment in the first column, the planner trap described here will feel familiar. If you don't, simpler planning approaches may already be sufficient for you.

Is the execution layer right for you?

|

Right For |

Isn’t Right For |

|

|

SLA Pressure |

Operations where SLA performance is contractually critical and routinely at risk, with penalties or escalations tied to missed SLA targets |

Operations where SLAs are loose, informal, or rarely enforced |

|

Operational Scale |

Multi-region, multi-depot field service organizations with 50+ technicians and overlapping service zones |

Small teams operating from a single depot with limited geographic spread |

|

Work Mix |

A complex mix of planned maintenance (PPM), reactive jobs, same-day callouts, and customer escalations |

Mostly pre-planned work with little to no same-day change |

|

Planning Workload |

Organizations where field service planners are under constant pressure, firefighting daily schedule changes |

Environments where planners make schedules once and rarely touch them again |

|

Change Frequency |

Operations experiencing frequent disruptions: delays, cancellations, technician absences, urgent requests |

Highly predictable operations with stable demand and minimal variability |

|

Coordination Complexity |

Teams coordinating across regions, depots, skills, priorities, and customer tiers |

Uniform technician roles with simple skill matching |

|

Business Objective |

Leaders actively trying to reduce missed SLAs without hiring more operations planners |

Teams focused primarily on basic dispatch or route visibility |

Adding planners is a natural response to SLA pressure, but it doesn't improve your SLA performance.

Each new planner absorbs complexity without reducing it. That creates coordination overhead, inconsistent decision-making, and diminishing returns.

Real SLA improvement requires an execution layer.

Only this can help you to handle real-time complexity, reprioritize dynamically, and automate trade-offs.

Systems like eLogii complement FSM tools, reduce human intervention, and free planners to focus on exceptions and strategic decisions.

So what's your next step?

Evaluate whether your planning team is growing faster than your operation.

If SLA performance remains unstable despite additional headcount, you may have fallen into the field service planner trap.

The only solution to your problem is mitigating complexity through better execution management. And we can help you with that.

Boost sales efficiency and profits with our route planner. Optimize routes, prioritize leads, and streamline field sales operations for maximum...

This article will reveal why you should start using a route planner to plan delivery routes and the eleven signs that your business really needs it.

Explore MapQuest's features, pricing, and tutorials in our comprehensive guide. Is MapQuest still relevant for your route planning needs? Find out!

Be the first to know when new articles are released. eLogii has a market-leading blog and resources centre designed specifically to help business across countless distribution and field-services sub sectors worldwide to succeed with actionable content and tips.