“With eLogii we gained a fast, flexible system that integrates into everything. We have 10x more speed and flexibility versus what we had before, planning time is down (60%+) with a leaner team than ever before and we produce executable, accurate routes that have our trucks going out 90%+ full. Furthermore, we can give our customers ETAs and tracking – they don’t need to call us any more to find our where things are. So - all in all the benefits we have gained from eLogii are tremendous” – Rafael Salinas – Head of International Operations

PORCELANOSA Group is one of the most important ceramics manufacturers in the world, offering furniture, kitchen and bath items, with over 970 stores in 150 countries around the world with a turnover of more than $1bn. Production diversification has played a key role in the growth of a business group that started off with the production of a single product: ceramic tiles. Today, the Group’s eight companies offer a wide product range that includes kitchen and bathroom equipment as well as state-of-the-art building solutions for contemporary architecture.

The problem

Porcelanosa and DHL (their UK 4PL partner) had for years used the same route planning tool but were beginning to be concerned by the lack of efficiency, high level of manual work and lack of flexibility of the tool. Practically it was also starting to cost them significant money as well and they required a scalable, flexible solution to run their successful and growing in-house delivery operation on.

“When we wanted to change something within a route on the old system, it would often take tens of minutes per stop – it was very complicated and lacked the flexibility we needed” - Ramon Prades – Lead Logistics Engineer

Due to peaks and troughs of volume during the year, a significant variety in product mix (big pallets, small pallets, different weights etc.) combined with a varied fleet mix (different vehicles and equipment types) the planning challenge was not an insignificant one.

“We were giving ETAs with 2/3 hour buffers in order to make the system-generated estimates somewhat accurate, and even then we would miss some deliveries. The algorithm just wasn’t up to the job of dynamic planning for our use case. We were seeking something more precise and accurate with true-to-life estimates that we could stand by” – Ramon Prades – Lead Logistics Engineer

When Porcelanosa approached eLogii, they had already trialled 5 or 6 solutions in the market but none were able to take all of these operational variables into account in a way that would product a planning result that the team knew they’d be able to execute.

As the customer is front and center of everything that Porcelanosa do, they were also looking for a solution (as well as the attributes above) that provided a stellar customer experience in line with the quality of their product (including accurate ETAs, tracking capabilities etc.).

As a data-driven organization, Analytics was also something important to Porcelanosa, and they were seeking a solution that would enable easy visualization of their key KPIs and performance against the same.

“We needed to have full control of our transport and furthermore we wanted an easy way to be able to review the plan for a day and be sure that things were efficient. That vehicles were travelling out full, but that windows were also going to be hit and the customer always satisfied. This kind of visibility and control is vital for our operations” - Rafael Salinas – Head of International Operations

Minimizing use of third-party less than truckload fleet was also a priority for Porcelanosa due to the fragile and delicate nature of some of their products (particularly ceramics).

“When we transport ceramics with our own fleet we know the breakage is 10x less than with LTL, but due to peaks and troughs of volumes and seasonality, it is difficult to predict how much capacity we need to buy. We want to keep it to a minimum and that is why optimization is so crucial for our business” - Rafael Salinas – Head of International Operations

Finally, Porcelanosa were looking for a solution which had an API first approach (and as a result a rich API and set of webhooks) to enable integration into their ERP system.

The Solution

With eLogii, Porcelanosa ticked all the boxes that they required from a solution and at the same time achieved this in a very user friendly format supported by world-class on boarding and implementation support.

“As well as the solution itself which is very flexible and powerful versus alternatives, the support you get from the team is second to none – they really listen, understand the business and care about the outcome they get for customers. That sometimes matters even more than the software itself, and it is rare!” - Rafael Salinas – Head of International Operations

Below we have explored some of the areas of the solution which gave Porcelanosa the best benefits which had the greatest positive impact on their operations.

Automated planning - taking into account business-specific rules

With eLogii, Porcelanosa was able to gain a system that allowed for the planning of hundreds of individual pallets leaving single depots within seconds (versus hours before).

Given the power of the optimization engine, Porcelanosa was able to take into account every conceivable operational parameter and set up their own rule sets (for example loading / unloading time for pallets between certain weights amongst many others).

Easy for operations team to make changes

Being able to make overrides or changes (if there is a specific business reason to do so) in a way that was quick and simple was a key requirement from the team at Porcelanosa and with eLogii they gained not only that but also a way in order to very quickly see what the impact on the plan was.

“Compared to the old solution where making a small change would break the whole plan, now we do it in 2 clicks and 10 seconds and we’re good to go” - Damian Rasielewski – DHL Logistics Team Leader UK

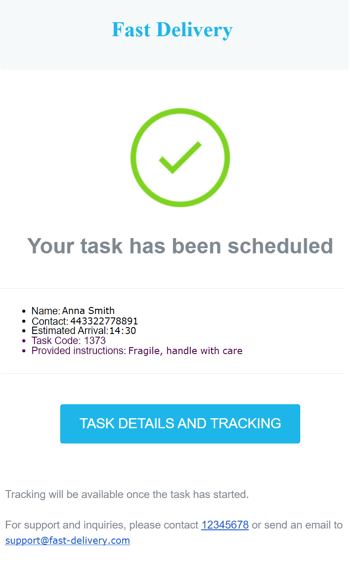

Customer communications, ETA and tracking

With eLogii, Porcelanosa gained class-leading customer communications and are able to provide live status updates and on-map tracking. SMS and email communications out-of-the-box mean that communications are automatically delivered from the system at exactly the right time in the lifecycle of an order.

“We now provide accurate ETAs that we trust – we know we can execute to that plan with 95%+ accuracy, just because of the number of factors the system intelligently takes into account in the plan. It is not just a theoretical plan that you get with so many solutions” - Rafael Salinas – Head of International Operations

Proof of Delivery

Porcelanosa required a solution which allowed for multiple photos to be taken as proof of delivery and for those photos to be shown clearly to the customer if they wanted to check delivered status of their order retroactively for example.

Out of the box eLogii provides a solution enabling a wide variety of proof of delivery options, from photos, signatures, barcode scans and more (as well as a combination of these).

“We particularly liked that you can make certain proof of delivery actions mandatory or optional – this really simplifies things from a driver’s perspective” - Damian Rasielewski - DHL Logistics Team Leader UK

.png?width=350&height=671&name=Multiple%20PODs%20(1).png)

Analytics

Analytics and reporting were key requirements Porcelanosa had when choosing a solution. They needed to be able to see how they were performing ‘today’ (i.e. live analytics) but also over a period of time. With eLogii Porcelanosa gained an unlimited look back window on data and a huge number of different analytics, enabling performance against all their key operational KPIs and more to be tracked.

“The dashboards give us a quick view of how we are performing and we are able to react accordingly if things are not going quite to plan” – Ramon Prades – Lead Logistics Engineer

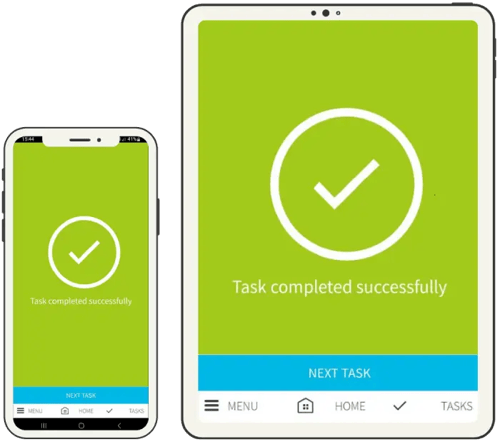

Simple but powerful driver app

eLogii’s driver app, downloadable from the iOS and Android play stores is running on the driver’s tablets which are in the cabs of the vehicles.

The app empowers drivers with an easy to use tool, from specific instructions, turn by turn

navigation, exceptions handling all the way though to sign on glass and photos.

Driver training on the app is simple and takes minutes versus hours (or even days) with some other solutions as a result of an intuitive and user friendly user experience.

The results

- 80% reduction in customer calls regarding orders

- 25% reduction in spend on external delivery companies

- 50% reduction in required planning FTEs for the same number of orders

- 10%+ improvement in vehicle utilization

- 81% reduction in planning time